Save dollars with reduced labour time

We significantly improve the overall efficiency of your industry through our years of applied practice. Our team of engineers, technicians and specialists are driven to upgrade, design and manufacture dense phase pneumatic conveying systems that:

Reliable engineers and technical specialists since 1982

Our service and design engineers take pride with their wealth of industry experience gained through more than 30 years of applied practice. Our decades of wisdom drawing upon decades of experience to augment scientific principles allow us to:

Request technical support to design pipes, assistance

and mechanical assembling

Our engineering experts are knowledgeable of specific material properties such as:

We design and customise dense phase pneumatic conveying systems

for your industry needs. Complete the form below to receive an

obligation FREE quote.

Dense phase pneumatic conveying systems inject less air and more materials into a conveying line. It offers the advantage of efficiently pushing a much denser concentration of bulk solids at relatively low velocities which makes it perfect for the following industries:

Dense phase pneumatic conveying systems preserve the integrity

of the materials conveyed, even in cases requiring the mixture of products which makes it ideal for these industries. Speak to us at

1800 786 642 if you need advice, assistance or pricing information for the products we deliver.

Dilute phase systems, such as blower and rotary valve, are relatively simple in comparison to dense phase systems, pressure pots.This makes it more economical, especially in relation to upfront investment costs. However, specialised industries often require high performance systems delivering minimal wear and tear of the conveying line and pipe elbows that is provided by dense phase systems.

Dense phase systems, if properly installed and designed by expert engineers like Pneuvay Engineering, results to more efficient energy cost. Talk to our friendly engineering experts at 1800 786 642 for additional questions concerning the difference of these two systems.

We are able to reduce the noise level below 85 dBA to suit your specific requirement. Complete our online form and we will respond to your query within the business day.

Our high performance pressure pots have the capacity to transport delicate and abrasive materials, such as glass, sand, and corundum.

We make use of low transport speed and rhino bends to reduce the shock to the pipe minimizing the abrasive properties of the materials when conveying abrasive material.

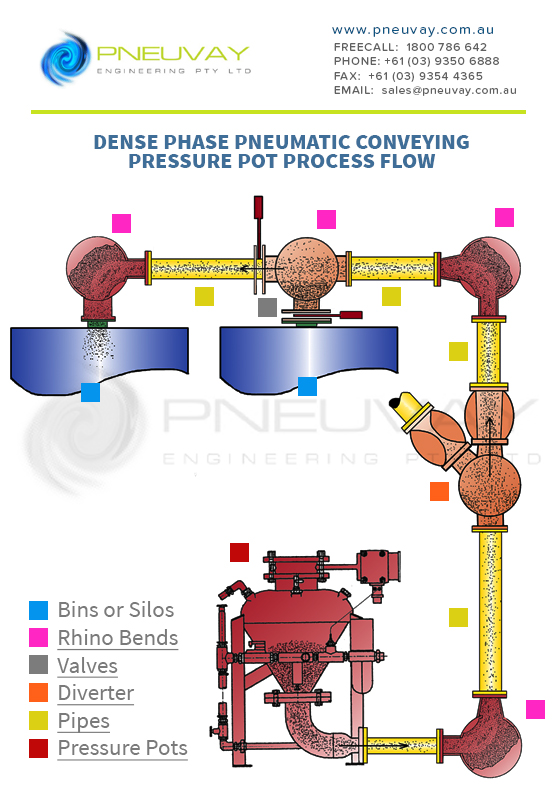

Dense Phase Pneumatic Conveying Pressure Pot Process Flow

Depending on the needs and on the product for transportation, you can choose between various methods. Speak to our expert engineers at 1800 786 642 to discuss your specific requirements.

Our dense phase pneumatic conveying systems are designed to deliver materials for both long and short transport routes. Complete our online form to get advice, assistance and pricing information relevant to your industry needs.

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags