We design, build and supply highly efficient blower enclosures for blower.

Pneuvay Engineering design, builds and supplies highly efficient blower enclosures for blowers - especially for LT and it's LTV roots blowers.

These blower enclosures are designed with a 8 to 15 dBA noise reduction (subject to site conditions) and come with the following features:

Features of Pneuvay Engineering's blower enclosures

We can achieve results down to 80 dBA. However, to get noise down to lower levels may require us to engage specialist noise engineers to plan in dealing with possible complications such as reflective sound from nearby surroundings.

Choose Pneuvay Engineering and experience the big difference these blower enclosures will bring to your business.

Choose Pneuvay Engineering and experience the big difference these blower enclosures will bring to your business.

Safe Work Australia in its Managing Noise and Preventing Hearing Loss at Work Code of Practice states the following:

"Designers and manufacturers of plant must ensure the plant is designed and manufactured so that its noise emission is as low as reasonably practicable.

"Officers, such as company directors, have a duty to exercise due diligence to ensure that the business or undertaking complies with the WHS Act and Regulations. This includes taking reasonable steps to ensure that the business or undertaking has and uses appropriate resources and processes to eliminate or minimise risks that arise from noise."

This statement prompts owners to ensure they implement appropriate measures to reduce noise emission in the workplace.

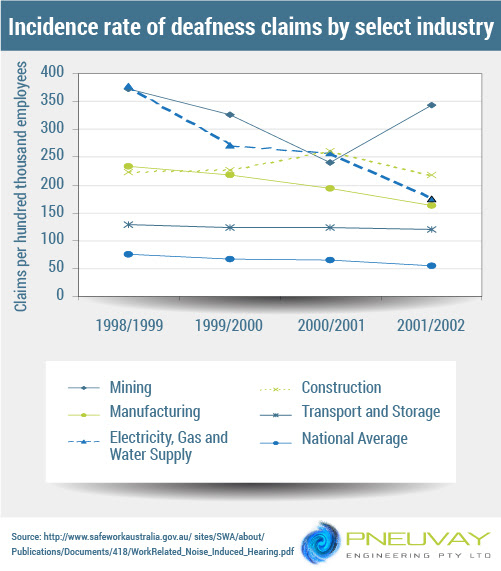

With more than one million employees potentially exposed to hazardous levels of noise at work and average deafness claims reaching as much as $30 million, it is of utmost important for businesses to ensure their workplace conforms to the minimum amount of noise level set by the Australian Occupational Noise Standard.

The following industries have the highest number of claims in Australia:

The mining industry holds the highest number of deafness claims in Australia primarily in the following fields:

The following manufacturing industries have received one of the highest deafness claims in Australia:

Given the various processes involved in the electricity, gas and water supply, statistics show it being the fourth largest culprit behind deafness claims.

The construction industry also shares a percentage in the number of deafness claims in the country.

With various forms of transportation in the country, it shows deafness claims in the following sectors:

Visit Safe Work Australia's to read more about

work related noise induced hearing facts.

Pneuvay Engineering has over 30 years of pneumatic conveying experience. It is highly skilled in designing the ideal blower enclosures for your equipment and systems. This includes carefully assessing the following:

Materials used in the constructions of blower enclosures

We sit with you to know all the elements to be taken into consideration. Talk to us at 1300 721 458, today.

Pneuvay Engineering's blower enclosures, although specifically designed for LTV roots blowers, can customized to be used for other applications such as:

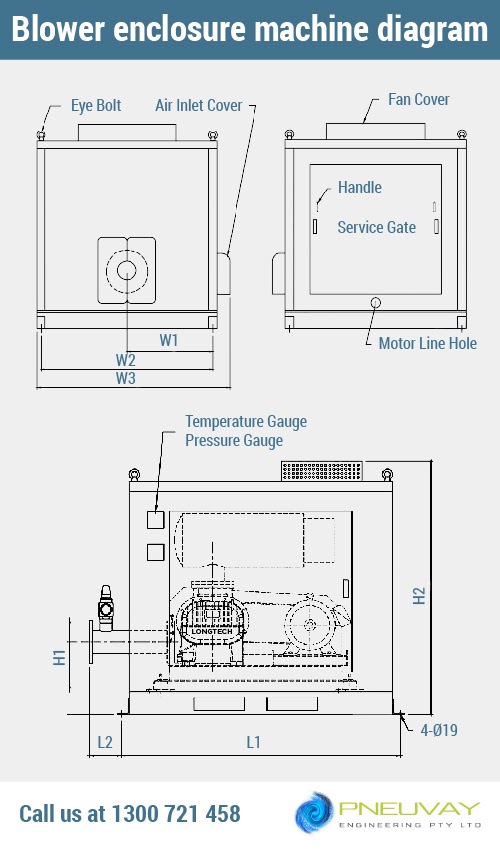

The image above shows the machine diagram of Pneuvay Engineering's blower enclosures

We are chosen by our clients for many reasons includings:

Visit our About Us section to learn more about Pneuvay Engineering.

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags