Dust Suppression Hopper (DSH) System for grain elevators,

fertilizer plants, quarries & mills.

Pneuvay Engineering is a proud global sales contact, agent and distributor of the multi-awarded Dust Suppression Hopper (DSH) System. We have been supplying this product range as part of service since 2009. Dust Suppression Hopper systems deliver:

This makes it perfect for many industries transporting granular or powdered materials. Especially those working with:

The Dust Suppression Hopper system is the preferred choice of many industries due to its unique and efficient features. This includes:

Aside from the unique features of the Dust Suppression Hopper system, it is also applauded by many businesses because of the following savings it delivers:

Choosing the dust suppression hopper system also adds the following benefits to your company:

Read details of these savings and benefits in the following blog.

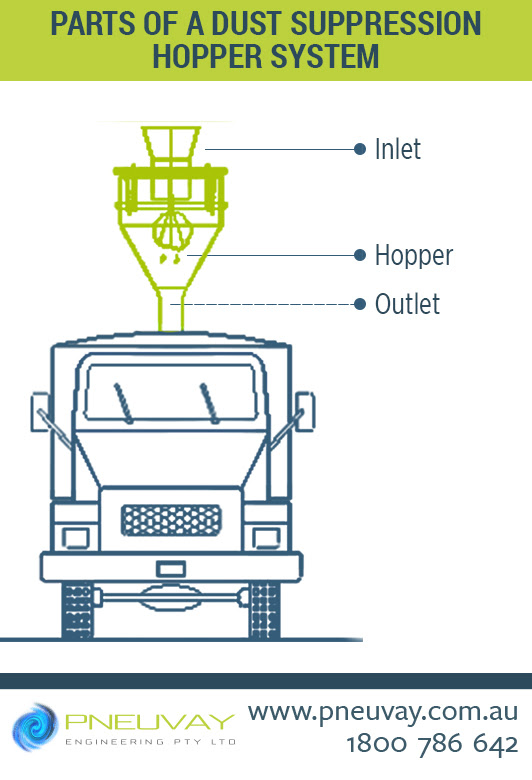

The Dust Suppression Hopper System is a material discharge apparatus patented system. It controls the flow rate of flowable materials being conveyed through a hopper. It is composed of the following:

Pneuvay Engineering showing parts of a dust suppression hopper system.

The Dust Suppression Hopper is installed under a feed point. Here it is where it is suspended above the target and kept at operating level. There is a small degree of natural agitation as the hopper is filled helps exclude air from the material being transferred.

During the point of loading or transferal, it concentrates the discharge of dry goods as a solid column through the free air that comes into any target repository. This include railcars, trucks, bags or stockpiles and storage containers.

Aside from the above-mentioned benefits, Dust Suppression Hopper System has also received several recognitions from various award giving bodies.

Australian Bulk Handling Awards 2013 - Finalist

Environmental Transport Award in Lloyds List Australia Shipping & Maritime Industry Awards

Australian Bulk Handling Awards 2012

AmCham DHL Express Success & Innovation Awards 2011

Australian Bulk Handling Awards - Dust Control Technology, Application or Practice

Innovative Technology award at the Australian Bulk Handling Awards

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags