and Vents

Our explosion panels and vents are designed to protect industries

against the damaging effects of dust and gas explosions.

We are a leader in the design, manufacture, certification and application of explosion panels and vents. We use advance cutting machinery, presses and machines to ensure all of our products and services deliver service beyond excellence. Moreover, we test our vent panels according to EN 14797 and manufactures these under the CE Examination certificate type INERIS 08TEX0038X.

Watch this live video footage and see how explosion vents and panels ensure safety in your workplace.

Explosion vents and panels are typically installed in high explosion risk zones where combustible dust cloud can easily generate such as:

Our products require little maintenance and are very easy to replace. Contact us and learn more about Pneuvay's explosion panels and vents to enjoy the following advantages:

Pneuvay Engineering designs specialised explosion panels

and vents to fit various industries such as:

Our explosion vent panels are designed to meet current health

and safety requirements and are intended to be used in potentially explosive areas (directive 94/9/CE). These panels are designed to evacuate the pressure in order to protect both the workforce and surrounding facilities in case of an explosion in the workplace.

These are simple and efficient protection systems that are designed to resist vacuum under cycling conditions and can also be applied to silos, cyclones, filter units and vessels.

All of our explosion vent panels are supplied with a certificate conformity complete with burst test results along with installation guidelines. This ensures that all of the products we deliver our clients are of the highest quality.

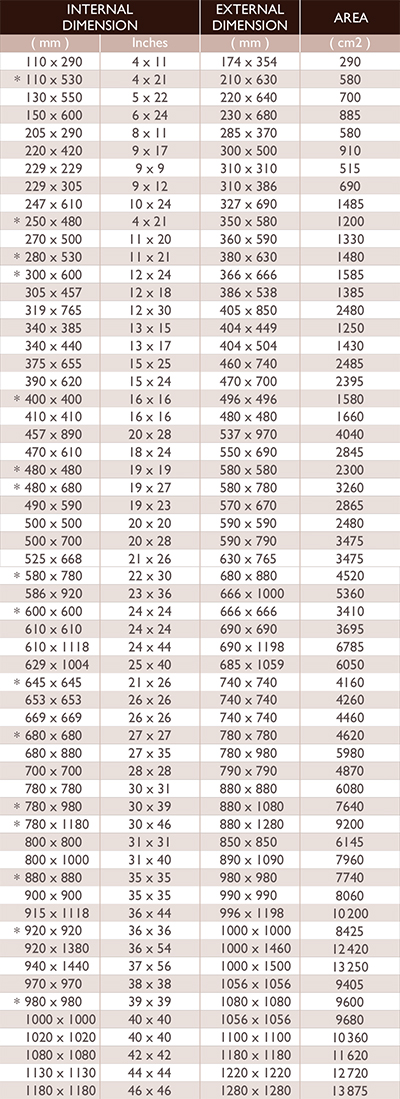

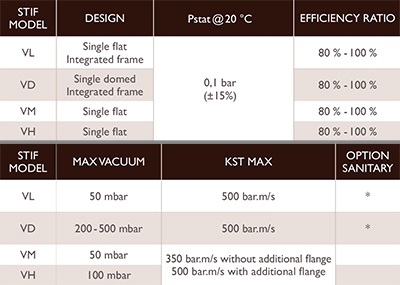

Vigilex VL Explosion Vent Panel Round Plat

This explosion vent panel is designed for single flat or round filters

with sanitary applications Standard Vacuum Resistance of 50 mbar

with these features:

Vigilex VD Explosion Vent Panel Round Plat

This explosion vent panel is designed for vacuum process with

pulsating or cycling Standard Vacuum Resistance of 200 mbar

with these features:

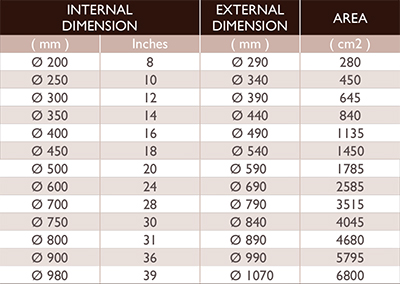

Vigilex VM Explosion Vent Panel Round Plat

This explosion vent panel is designed for round applications

such as filters and silos with Standard Vacuum Resistance

of 50 mbar with these features:

Vigilex VH Explosion Vent Panel

This explosion vent panel is designed for single flat and high performance pulsating applications with Standard Vacuum Resistance

of 100 mbar. Its additional features are:

Vigilex Flameless Explosion Venting

This is a recent add-on to the Vigilex Explosion Vent Panel family. It helps protect indoor machines, such as Bucket Elevators, were vent panels are not acceptable. This makes it the right solution for an economical and safe protection of equipment.

The Vigilex Flameless is available in different sizes and is certified

with an EC Certificate by INERIS. Our technical team is ready to

study the quantity and size of the Flame Arrestor necessary to

protect your installation. We warrant a high technology product

with the latest standards and the best quality price ratio in the

market today. Contact us to learn more about our pneumatic

conveying products and services.

We take pride in supplying high quality products and services to our clients in Australia and around the globe. We tailor our services to fit your every need and concern. Contact us to learn more about the pneumatic conveying products, systems and services we offer.

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags