Our fans and blowers are suitable for both pressure and vacuum applications for a myriad of different situations and are effective in wide range of industries.

We offer variety of pneumatic fans and blowers such as:

Each rotor of a Roots Type Blower turns at an equal speed, but in the opposite direction to the other. This is achieved by using a pair of equal ratio gears to drive the rotors. Using this type of configuration, blowers can run without internal lubrication to the rotors, as they never come into contact with either the outer casing or each other; thus air is delivered completely oil free.

As the rotors turn, air is drawn into the inlet side of the blower and travels around the outer casing of the machine in the pockets between each lobe of the rotor. Once at the discharge side of the blower, the air is forced out and stopped from passing back into the chamber by the finite clearances between all its internal components. The tiny amount of air that does manage to pass back through these minute clearances is what's known as the blowers "Slip".

There is no change to air volume within the blower (i.e. no air compression takes place). The air is simply displaced from the intake side to the discharge side of the blower against the resistance of the system pressure. Roots blowers are therefore able to deliver a constant airflow that is independent of the discharge pressure conditions with the rate of flow largely determined by the blowers operating speed.

An example of how a positive displacement blower works.

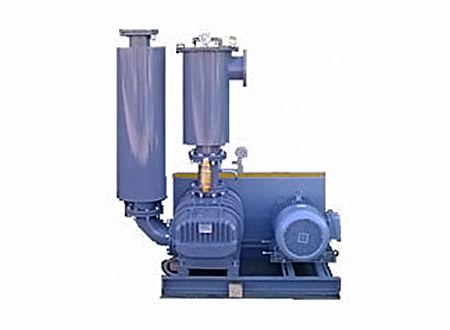

Pneuvay LT Series Blowers Vacuum Unit

The Pneuvay LT series three lobe roots type blowers are a new series of roots type blowers. The three lobe design provides better air performance, lower vibrations and noises that is a significant improvement on the traditional two lobe roots blowers.

Traditional roots blowers lubricate bearings and gears with grease and oil, but the Pneuvay LT series is designed to add oil only. It is very easy to maintain as oil has better lubricating properties than grease. Moreover, it delivers:

Our blowers are suitable for both pressure and vacuum applications for a myriad of different situations and is effective

in the following industry processes:

* Noise level is an approximate only and will vary depending on the site conditions

** Weight approximate not including the motor.

* Noise level is an approximate only and will vary depending on the site conditions

** Weight approximate not including the motor.

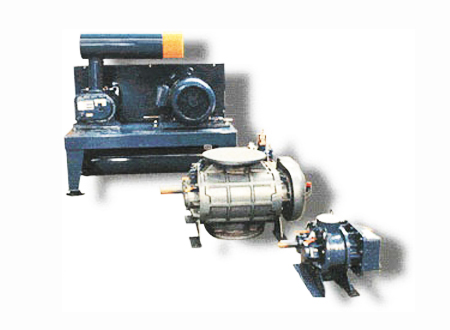

Pneuvay Wade Blowers twin rotors blower with extremely close tolerances

for maximum energy efficiency.

Both blowers and exhausters are often referred to as "blowers" in pneumatic conveying and we supply various root type blowers for all applications, one of which is the world renowned Wade blowers.

With the many products in the industry, we choose to supply the renowned Wade blowers. These are manufactured with twin rotors with extremely close tolerances that ensures maximum energy efficiency.

Wade blowers are suitable for both pressure and vacuum applications for a myriad of different situations and a wide range of industries including:

Our Wade Blowers are suitable for various industry applications. See the maximum energy efficiency each of these Wade Blowers provide.

This graph shows the various performance efficiency rate of the different types of Wade Blowers.

This table features the different Pneuvay Wade Blower models specifying its air flow (m3/hr), maximum pressure (m bar) and maximum speed (rpm) performance. It also classifies these Wade Blowers as:

We take pride in supplying high quality products and services to our clients in Australia and around the globe. We tailor our services to fit your every need and concern. Contact us to learn more about the pneumatic conveying and industrial vacuum products, systems and services we offer.

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags