Our Rhino Bend is a new development in pneumatic conveying which

solves many of the problems associated with conveying abrasive materials.

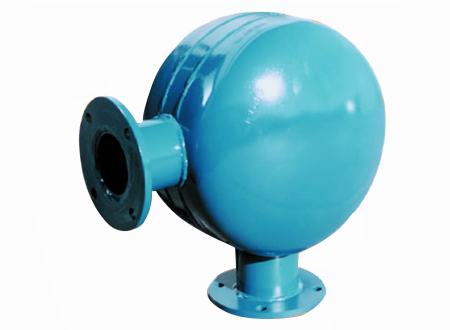

The Rhino Abrasive Bend is a new development in pneumatic

conveying which solves many of the problems associated with

conveying abrasive materials.

Pneuvay Engineering Rhino Bends provides solutions to many of the problems associated with conveying abrasive materials.

Prior to the development of Rhino Bend, many pneumatic conveying systems experienced extremely high resistance across bends; thus dramatically reducing the efficiency of the system. Moreover, the speeds at which these materials were conveyed often caused the bends to wear through prematurely.

Pneuvay Engineering greatly reduces these losses and protects the bend from wearing through the development of the Rhino Bends. It decreased the velocity of the outermost material by utilising an over-sized radius. With this approach, the material tends to form a stationary buffer layer which protects the interior of the joint. As a result, the bend will not suffer from the normal abrasion associated with conveying heavy materials.

Pneuvay Engineering's Rhino Bends have the following advantages:

We supply various Rhino Bend model and sizes to meet our client's individual needs. See this table to the specifications of:

We take pride in supplying high quality products and services to our clients in Australia and around the globe. We tailor our services to fit your every need and concern. Contact us to learn more about the pneumatic products, systems and services we offer.

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags