We are a supplier of Vortex's innovative

valve products for dry bulk material handling in Australia.

Choose from the range of valve solutions we offer.

Vortex is a brand known around the globe for its exceptional valves for handling dry bulk solids. It's current footprint allows it to introduce lean manufacturing methods supported by laser cutting technology and advanced fabrication equipment. It has expanded and modernize to better improve the level of satisfaction it delivers to its client and Pneuvay Engineering is proud to offer the same high quality of products and services to its customers.

Learn about the numerous pneumatic conveying advantages it brings to industries such as:

We offer a wide range of diverter products from Vortex. Choose from our list of products below:

The 2-Way Wye Line Diverter is specifically engineered to handle dry

bulk solids in vacuum with pressure up to 15 psig (1barg).

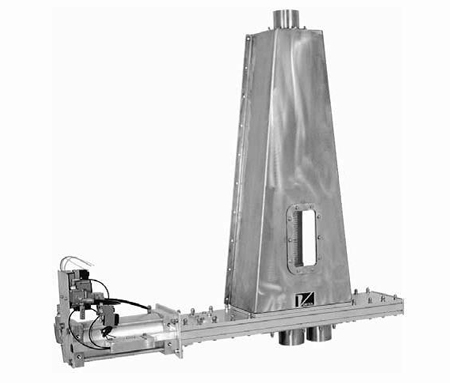

The patented Vortex© Quantum® Series 2-Way Wye Line Diverter ™ is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressure up to 15 psig (1 barg).

This is designed to eliminate problems and increase productions, while decreasing labour and equipment costs. Its full flow orifice provides unrestricted conveying of material with no disk or ledges to impede flow while its diverter seat and live-loaded seals are shielded from abrasion by a metal insert that provides superior shearing action.

The 3-Way Wye Line Diverter is specifically engineered to handle dry bulk

solids in vacuum with pressure up to 15 psig (1barg).

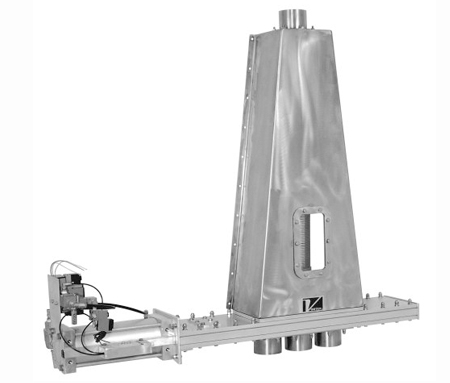

The patented Vortex© Quantum® Series 3-Way Wye Line Diverter ™ is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressure up to 15 psig ( 1 barg).

The 3-Way Wye Line Diverter is designed to eliminate problems and increase production, while decreasing labour and equipment costs. It's full flow orifice provides unrestricted conveying of material with no disk or ledges to impede flow. The diverter seat and live-loaded seals are shielded from abrasion by a metal insert, which provides superior shearing action.

Note: Refer to 3-Way Wye Line Gate PDF for complete specification of the product.

The 4-Way Wye Line Diverter is specifically engineered to handle

dry bulk solids in vacuum with pressure up to 15 psig (1barg).

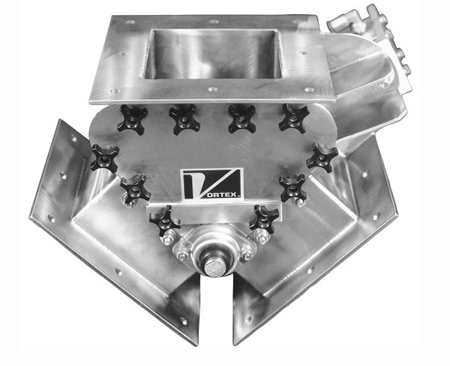

The patented Vortex© Quantum® Series 4-Way Wye Line Diverter ™ is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressure up to 15 psig ( 1 barg).

The 4-Way Wye Line Diverter ™ is designed to eliminate problems and increase production, while decreasing labour and equipment costs. Its full flow orifice provides unrestricted conveying of material with no disk or ledges to impede flow while its diverter seat and live-loaded seals are shielded from abrasion by a metal insert, which provides superior shearing action.

The Vortex ® Multi-Port Wye Line Diverter ™ is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressure up to 15 psig ( 1 barg).

The Multi-Port Way Wye Line Diverter ™ is designed to eliminate problems and increase production, while decreasing labour and equipment costs. Its full flow orifice provides unrestricted conveying of material with no disk or ledges to impede flow while its diverter seat and live-loaded seals are shielded from abrasion by a metal insert, which provides superior shearing action.

Note: Refer to Multi Port Wye Line Diverter PDF for complete specification of the product.

The Multi-Port Wye Line Diverter has the ability to shift

without shutting down blower.

The 2-Way Flex Tube Diverter has a smooth unobstructed transition

from inlet to outlet that shields the wear compensating seals from abrasion.

The Vortex ® 2-Way Flex Tube Diverter ™ is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressure up to 15 psig ( 1 barg).

The 2-Way Flex Tube Diverter ™ is designed to eliminate problems and increase production, while decreasing labour and equipment costs. Its unique design eliminates material cross contamination by a positive seal across the closed port and the elimination of internal ledges and pockets where material can lodge and remain trapped, while its smooth unobstructed transition from inlet to outlet shields the wear compensating seals from abrasion.

Note: Refer to Pneuvay 2-Way Flex Tube Diverter PDF for complete specification of the product.

The 3-Way Flex Tube Diverter has a smooth unobstructed transition

from inlet to outlet that shields the wear compensating seals from abrasion.

The Vortex ® 3-Way Flex Tube Diverter ™ is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressure up to 15 psig ( 1 barg).

The 3-Way Flex Tube Diverter ™ is designed to eliminate problems and increase production, while decreasing labour and equipment costs. Its unique design eliminates material cross contamination by a positive seal across the closed port and the elimination of internal ledges and pockets where material can lodge and remain trapped, while its smooth unobstructed transition from inlet to outlet shields the wear compensating seals from abrasion.

Note: Refer to Pneuvay 3-Way Flex Tube Diverter PDF for complete specification of the product.

The Fill Pass Diverter provides a versatile and reliable method for filling one or more "in-line" weigh hoppers.

The Vortex ® Fill Pass Diverter ™ is specifically engineered to handle dry bulk solids in vacuum or dilute phase pneumatic conveying systems with pressure up to 15 psig ( 1 barg).

The Fill Pass Diverter ™ is designed to eliminate problems and increase production, while decreasing labour and equipment costs. It provides a versatile and reliable method for filling one or more "in-line" weigh hoppers when material is being conveyed pneumatically through a closed loop system.

Note: Refer to Pneuvay Fill Pass Diverter PDF for complete specification of the product.

The 2-Way Seal Tite Diverter

offers a removable door access

for replacement of blade and shaft seals.

The blade seal of the 2-Way Seal Tite Diverter is protected from abrasion.

2-Way Seal Tite Diverter has access door for internal inspection,

cleaning or maintenance.

The Vortex ® 2-Way Seal Tite ™ Diverter is designed for use in gravity flow applications where material can be diverted from one source to either of two destinations.

The 2-Way Seal Tite ™ Diverter's superior design promotes efficiency, durability and long service life. It offers a removable access door for replacement of blade and shaft seals and all internal ledges have been eliminated to promote cleanliness.

Note: Refer to Pneuvay 2-Way Seal Tite Diverter PDF for complete specification of the product.

The 3-Way Seal Tite Diverter offers a removable door access for replacement

of blade and shaft seals.

The Vortex ® 3-Way Seal Tite ™ Diverter is designed for use in gravity flow applications where material can be diverted from one source to either of three destinations.

The 3-Way Seal Tite ™ Diverter's superior design promotes efficiency, durability and long service life. It offers a removable access door for replacement of blade and shaft seals and all internal ledges have been eliminated to promote cleanliness.

Note: Refer to Pneuvay 3-Way Seal Tite Diverter PDF for complete specification of the product.

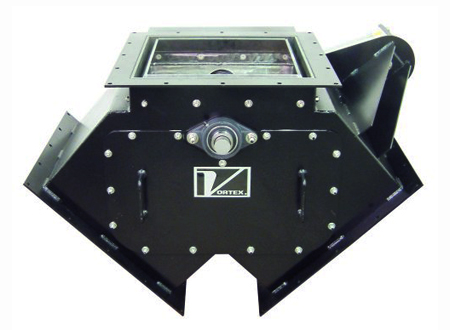

The Abrasive Duty Diverter has been engineered to address problems

associated with typical aggregate or "bucket" diverters.

The Abrasive Duty Diverter has connection options for

SVC Standard Flange, ANSI, DIN, JIS, or Custom Flanges.

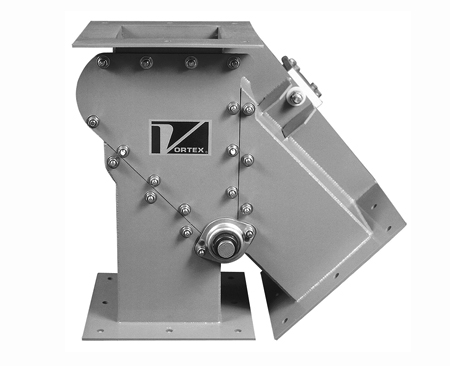

The Vortex ® Abrasive Duty Diverter ™ is designed to meet the demanding applications associated with handling material such as sand, gravel, whole grains and coal.

The Abrasive Duty Diverter is designed to eliminate problems, increasing production while decreasing labour and equipment costs. It has been engineered to address the problems associated with typical aggregate or "bucket" diverters. The removable access door and abrasion resistant wear liners allow for a "maintenance friendly" diverter.

Note: Refer to Pneuvay Abrasive Duty Diverter PDF for complete specification of the product.

The Gravity Dee Diverter is capable of metering flow in

both or either direction.

The Vortex ® Gravity Vee ™ Diverter is designed for diversity when diverting the flow of dry bulk solids in a gravity flow conveying system.

The Gravity Vee ™ Diverter is designed to eliminate problems and increase production while decreasing labour and equipment costs. The design allows for material flow through both outlets simultaneously, one outlet at a time, or a complete shut-off of flow. It is also capable of metering flow in both or either direction.

Note: Refer to Pneuvay Gravity Vee Diverter PDF for complete specification of the product.

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags