We are a supplier of Vortex's innovative

valve products for dry bulk material handling in Australia.

Choose from the range of valve solutions we offer.

Vortex is a brand known around the globe for its exceptional valves for handling dry bulk solids. It's current footprint allows it to introduce lean manufacturing methods supported by laser cutting technology and advanced fabrication equipment. It has expanded and modernize to better improve the level of satisfaction it delivers to its client and Pneuvay Engineering is proud to offer the same high quality of products and services to its customers.

Learn about the numerous pneumatic conveying advantages it brings to industries such as:

We offer a wide range of slide gate products to fit specific industry needs. Choose from any of the pneumatic conveying products listed below:

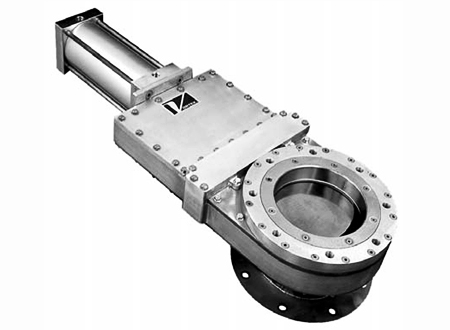

Vortex® Quantum® Series Orifice Gate™ is designed to prevent

industries from frequent valve maintenance, production inefficiencies

and unsanitary environments.

Unlike common knife gates and butterfly valves sold in the market today, the Orifice Gate has been specifically engineered to handle dry bulk powders,granules and pellets. These knife gates rely on its soft elastomeric seals that erode or tear away in service while its butterfly valves has incorporate discs that cause significant flow restrictions resulting to an impacting system performance and throughput. Thus, both designs leads to the efficient promotion of wedging and packing of materials, as well as the prevention of positive air and material shut off.

The patented Quantum® Series Orifice Gate™ is specifically designed to handle dry bulk solids in gravity flow, dilute phase, or vacuum conveying systems providing the following benefits to industries:

A full flow orifice provides unrestricted pneumatic conveying of material with no disk or ledges to impede flow or to cause material bridging. The gate seat and live-loaded seals are shielded from blast abrasion by a metal insert, which provides a smooth bore through the valve improving performance and decreasing any pressure drop across the orifice. By design, the valve "self cleans" material from the seat on each stroke of the valve blade, improving overall seat life.

The Vortex® Quantum® Series Orifice Gate™ features:

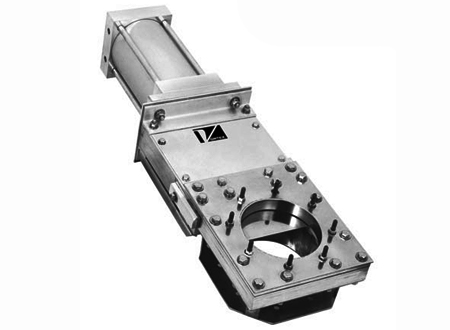

The unique "rising" blade design of the patented Vortex® HDP® Slide Gate sets itself apart from traditional industry slide gates by providing positive material shut-off in applications. It offers the durability and efficiency required to meet today's material processing demands.

Traditional slide gates or butterfly valves are designed to handle gases and liquids, but not dry materials. These valves rely on soft seals that are susceptible to blast abrasion and material packing, which eventually produces leakage of air and material through the valve or to the atmosphere. This results to:

The Vortex® HDP® Slide Gate is designed to prevent these problems, enabling you to meet your objectives by increasing production while decreasing labour and equipment costs.

Watch this video to see the many amazing features of the HDP Slide Gate.

The Vortex® HDP® Slide Gate features:

Note: Refer to Pneuvay HDP Slide Gate PDF for complete specification of the product.

The Vortex® HDP® Slide Gate is designed to provide positive material

shut-off in applications.

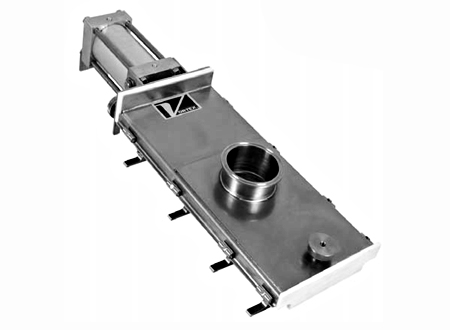

The patented Vortex® Clear Action Gate™ is a problem solver specifically

designed for demanding dry bulk material applications.

The patented Vortex® Clear Action Gate™ is specifically designed for demanding dry bulk material applications. It is a high quality yet economical valve used in pneumatic conveying systems that allows up to 15 PSIG ( 1 Barg.) It sets itself from other pneumatic conveying equipment with its remarkable features such as:

Traditional knife gates or butterfly valves are designed to handle gases and liquids, but not dry materials. These valves rely on soft rubber seals that erode or tear away during use; thus allowing leakage of air and material through the valve or into the plant's atmosphere. As a result, production and operation suffer from:

The Clear Action Gate™ is designed to eliminate these problems, enabling you to meet your objectives by increasing production while decreasing labour and equipment costs.

The Vortex® Clear Action Gate™ features:

Note: Refer to Pneuvay Clear Action Gate PDF for complete specification of the product.

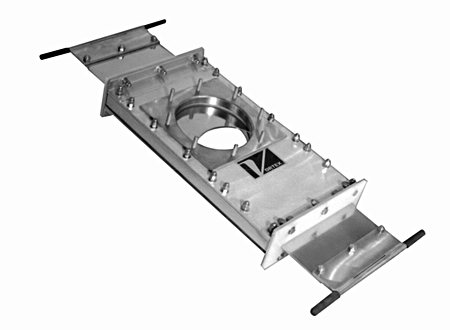

Vortex® Quick Clean Orifice Gate™ is a Clean Out of Place gate valve

designed for frequent cleaning.

The Vortex® Quick Clean Orifice Gate™ is a Clean Out of Place gate valve designed for frequent cleaning. It is designed to eliminate problems allowing you to meet your objectives by increasing production while decreasing labour and equipment costs.

The full port opening and self cleaning design of the Quick Clean Orifice Gate allows it to be disassembled and assembled in minutes without any tools. It can even be modified to meet the USDA Dairy Standard Accepted rating making it an excellent choice for applications requiring daily sanitation of equipment, like the food processing industry.

The Quick Clean Orifice Gate™ features:

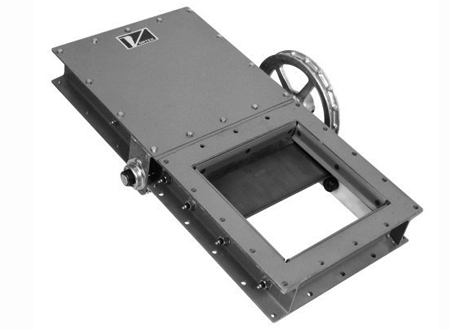

Vortex® Maintenance Gate™ is the best choice when material needs

to be positively isolated in a hopper or silo, while maintenance is being

performed on equipment below.

The Vortex® Maintenance Gate™ offers quality features at an economical price. It is available in a wide variety of configurations, including round inlet/outlet transitions. It is most definitely your best insurance policy against equipment failure.

This gate is the best choice when material needs to be positively isolated in a hopper or silo while maintenance is being performed on equipment below. In the open position, the Vortex® Maintenance Gate™ positively seals conveying air to atmosphere.

The Maintenance Gate™ features:

Note: Refer to Pneuvay Maintenance Gate PDF for complete specification of the product.

Vortex ® Roller Gate ™ is the best choice for handling dry materials in

gravity flow applications where positive material shut-off.

The Vortex ® Roller Gate ™ offers quality features at an economical price. Processes and operations will greatly benefit from it particularly in industries that require the best choice for handling dry material.

The Vortex ® Roller Gate ™ is your best choice for handling dry materials in gravity flow applications where positive material

shut-off and dust tight sealing are required in compact locations.

It is also available in a wide variety of configurations to meet

customer requirements including rectangular sizes and customer specific hole patterns.

The Roller Gate ™ features:

Note: Refer to Pneuvay Roller Gate PDF for complete specification of the product.

Hand Slide Orifice Gate™ with 316L Stainless Steel Material Contact

The Vortex® Hand Slide Orifice Gate™ is designed to specifically to handle dry bulk solids in gravity flow conveying. It offers the durability and efficiency required to meet today's material processing demands.

Traditional knife gates or butterfly valves are designed to handle

gases and liquids, but not dry materials. These valves rely on soft

rubber seals that erode or tear away during use; thus allowing

leakage of air and material through the valve or into the atmosphere.

As a result it leads to:

The Hand Slide Orifice Gate™ is designed to eliminate these problems, enabling you to meet your objectives by increasing production while decreasing labour and equipment costs.

The Hand Slide Orifice Gate™ features:

Note: Refer to Pneuvay Hand Slide Orifice Gate PDF for complete specification of the product.

Vortex® Dual Cylinder Roller Gate™ is your best choice for handling dry material

in gravity flow applications where positive material shut-off and dust tight sealing

are required in compact locations.

The Vortex® Dual Cylinder Roller Gate™ offers quality features at an economical price. It offers durability and efficiency required to meet today's material processing demands.

The Dual Cylinder Roller Gate is your best choice for handling dry material in gravity flow applications where positive material shut-off and dust tight sealing are required in compact locations. It is available in a wide variety of configurations including rectangular sizes and round inlet/outlet transitions.

The Dual Cylinder Roller Gate™ features:

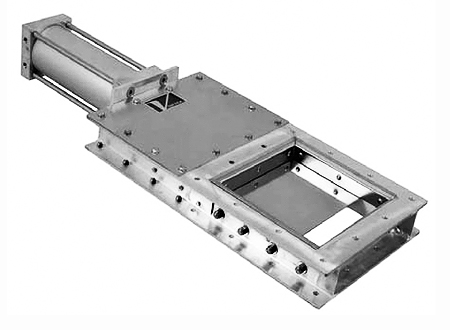

The Vortex Abrasive Duty Gate is designed to meet the demanding applications associated with handling material such as sand, gravel, whole grains and coal.

The Abrasive Duty Gate is designed to eliminate problems and increase production, while decreasing labour and equipment costs. Its narrow profile, choice of actuators and custom rectangular size makes this slide gate adaptable to most existing installations. It also offers optional round inlet or outlet flanges and dust return pans.

The Abrasive Duty Gate offers optional round inlet or outlet flanges

and dust return pans.

Note: Refer to Pneuvay Abrasive Duty Gate PDF for complete specification of the product.

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags