See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, December 15, 2021

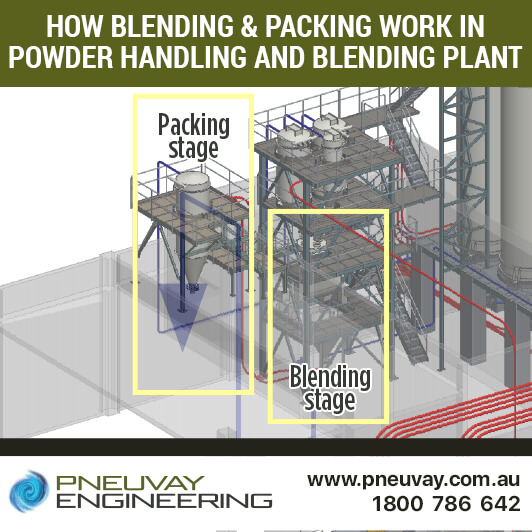

The workings of the two remaining production sections (blending and packing stages) of the chocolate milk powder handling plant are covered off in this case study. We describe how the weighed and batched materials from the weighting hoppers are blended (pre-mix, creamer, processed sugar, milk powder, whey and cacao), then transferred for packing.

How the blending and packing stages work at the chocolate milk powder handling and blending plant

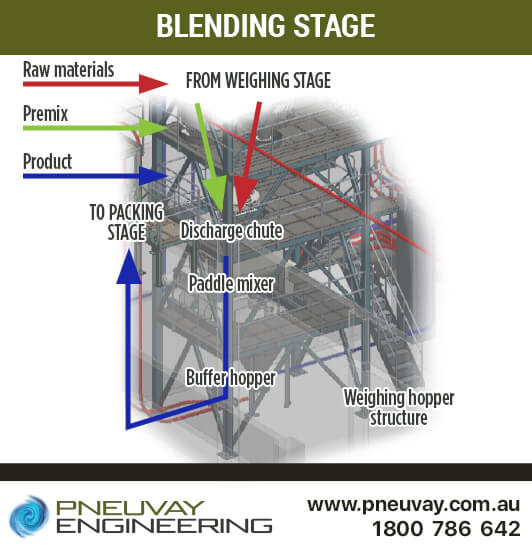

The blending stage receives weighed material from the processing stage to produce a final product. This is fed to the packing stage on a continuous basis. From the four weight hoppers, raw materials and minor ingredients are dispensed into the paddle mixer through a four-inlet discharge chute. Each inlet for the chute has an inspection port and is made of 304 stainless steel. The paddle mixer blends these powders into the final product and drops it into the buffer hopper below. The mixer, made of 316 stainless steel, has a local control panel. Batches are transferred from the buffer to the receiving hopper using dense phase vacuum conveying, with cool dry air from the blower and booster fan processed by the dehumidifier.

When it comes to powder handling, blending materials is not the same as mixing materials. More on difference between mixing and blending in powder food processing.

We have included a set of pictures showing the paddle mixer used, how it works and how it integrates in the blending stage.

Check out the following:

Blending stage of powder handling and blending plant

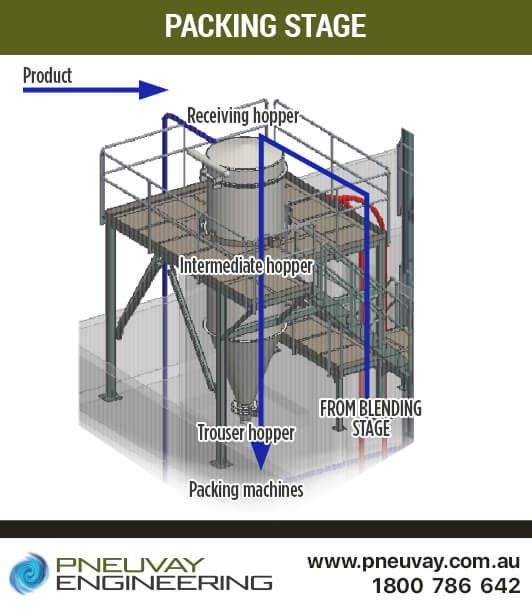

The packing stage receives the final product from the blending stage. Two receiving hoppers in the packing stage are fed final product from the buffer hopper under the paddle mixer. The flow of final product to the receiving hoppers is continuous and controlled remotely with a diverter gate near the buffer hopper. The final product is then fed to the intermediate hopper and then to the trouser hopper. From there it is dispensed to packing machines that fill bags of the final product into 500g and 1kg packs. The installation of these small bag filling systems was not part of the project, only their integration with the trouser hopper.

The packing stage is fully automatic and provides continuous feeding. When the receiving hopper is detected as empty, a low-level sensor sends a request to the PLC to dispatch a new batch from the buffer hopper, which was filled earlier by the paddle mixer. This ensures the intermediate hopper always contains some final product ready to dispense.

The intermediate hopper is made from 304 stainless steel and has an inspection hatch and a vent sock. It is connected to the receiving and trouser hopper with BFM flexible connectors and spigots.

This custom piece of equipment is called a trouser hopper because it looks like the top of a pair of trousers. It is a twin-head feeding machine that evenly dispenses the final product down two paths.

This case study includes images showing the hoppers and how they are interconnected in the packing stage. Detailed descriptions of the hoppers and how they integrate into the plant are provided.

Check out the following:

Packing stage of powder handling and blending plant

The blending and packing stages within the plant uses dense phase vacuum conveying (DPVC) to transfer the powder ingredients. A dense phase pressure conveying system transports final powder product from the buffer hopper under the blender to the receiving hopper above the packing machines. Close to the receiving hopper are vacuum pumps used to generate the dense phase pressure conveying system. To prevent pipeline condensation, cool dry air is supplied from the dehumidifier and booster fan from the plant room on the opposite side of the complex (near the silos).

For a complete examination of the pneumatic conveying, equipment and components within the chocolate milk powder handling and blending plant.

This example of this powder handling and blending plant project is detailed and broken into several major sections including:

The combined resources of Pneuvay with our Pneu Powders Systems group makes us a market leader for large-scale blending and packing systems for powder handling plants. We can provide our engineering expertise locally in Australia and New Zealand, as well as, throughout the Asia-Pacific and Middle East. Contact us if you need assistance in blending and packing for your powder handling and blending plant. Call on 1300721458, contact us with our online form or message us on our Facebook page.

Get social with us and see the latest news items from:

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541