See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Tuesday, November 26, 2024

When you are involved in the transfers of bulk powder and grains, understanding how airslide conveyor systems work will be of help as it is the 'best-fit' solution for many industrial circumstances.

Airslides provide some of the most efficient and practical methods of conveying bulk powder material. With some low pressure air, an aeration bed and a small incline (gravity), we can convey hundreds of tonnes of products over long distances.

Airslides are used extensively in many industries, including mining. They convey homogenous dry powder, including minerals, for use in cement, lime and fly ash. The food industry uses airslides for flour, and many powders in the chemical industry are ideally suited to airslides.

Airslides have no moving parts. They are, therefore, often a far better solution than screw conveyors, drag chains and belt conveyors.

Understanding how air slide conveyor systems work

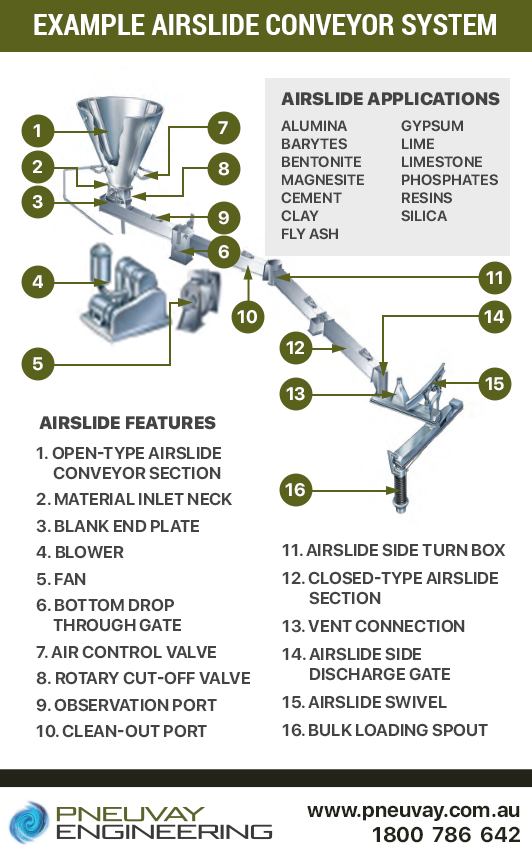

Some of the basic structural features of an air slide conveyor system include:

Several point of how air works with the airslide conveyor system include:

A typical airslide installation in a cement depot will convey cement (bulk powder) some distance from a silo discharge. Ultimately, it discharges cement into a tanker via a loading chute.

Example of an airslide conveyor system

Pneuvay airslides, unlike those from other suppliers, install a perforated metal support sheet under the aeration cloth. This provides stability and less movement of the fabric while conveying. This will extend the life of the cloth.

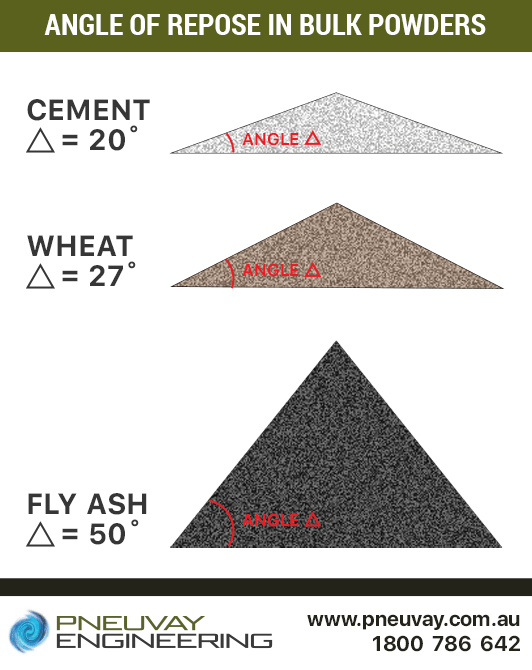

On a permanent equilibrium the angle of repose of bulk materials naturally achieves a constant slope from the horizontal plane. This is shown in the figure below.

Angle of repose of bulk powders

To properly allow the transported material to flow, it was necessary to draw conveyor systems with a slope greater than the angle of repose of the material. These, however, have caused more complications, resulting in the invention of fluidised conveying systems. These are also known as airslide conveyor systems or air gravity conveyors.

Airslide conveyor systems use a technique that maintains the aerated condition of the bulk material. This is illustrated and explained in this video below.

How fluidisation of powder works

This is implemented from the time it is introduced into the upper end of the channel to the point where it is unloaded.

How is this possible?

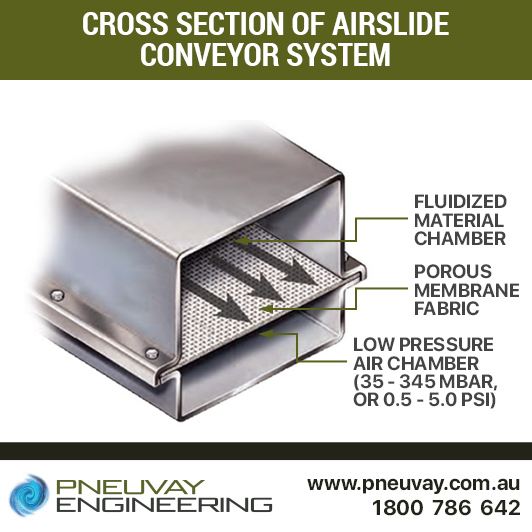

The airslide is a metal box divided into two parts:

A porous fabric membrane is located between the two parts of the housing.

Cross section of airslide conveyor system

The air thus passes through a false bottom or membrane made of a suitable porous material (polyester). This membrane extends over the entire length of the airslide, as shown below:

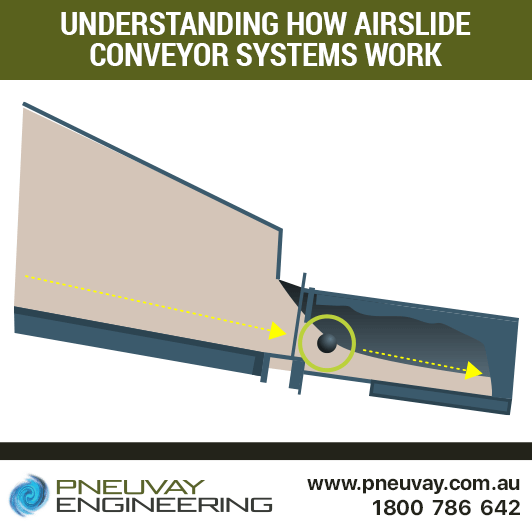

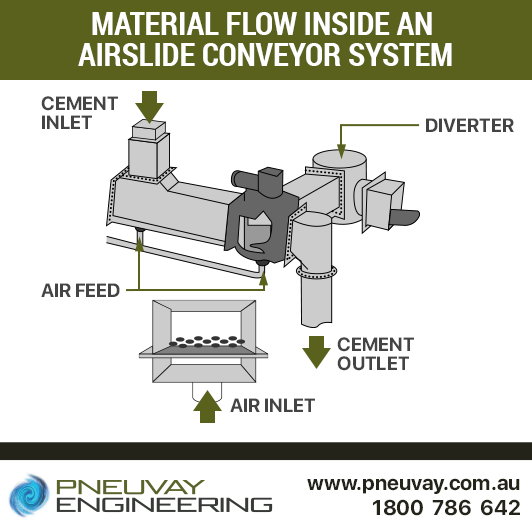

Material flow inside an airslide conveyor system

The principle of operation behind an airslide system is driven by the fluidising air. After passage through the bed of material sliding over the membrane, the substance flows over the bed of material and is discharged through a suitable filtration unit.

Since the material is maintained by means of the regular air flow, it flows freely down the slope, even when the inclination angle is relatively small.

The amount of air used is kept to the minimum necessary to reduce the interparticle force and the frictional forces between particles and surfaces of the inner channels, sufficient to allow the flow of material.

An airslide conveyor system dimensions include:

These are straightforward to calculate.

The width of an airslide system is calculated based on the capacity and the material density of the powder transported

The length of the airslide system does not have any specific limitation.

The angle of inclination may vary depending on the type of material being conveyed. It is based on the principle that the more fluid the material is, the less the airslide needs to be inclined.

The airslide conveyor system is the preferred choice for many industries because of its:

This makes it an ideal choice for transporting bulk powders applications such as:

The design and installation of airslide conveyor systems can be complicated. Meticulous and exact calculations are required. For this you need a pneumatic conveying company with years of experience that can deliver the results you wanted.

Below are some of the airslide conveyor system projects we have completed through the years.

A complete airslide AS500 package was required for the Queensland Alumina Ltd project. All components were manufactured in Melbourne. Read more this QAL airslide conveyor project.

Queensland Alumina airslide conveyor system project

Pneuvay supplied Blue Circle Southern Cement (BCSC) a complete set of AS400 and AS300 airslides for their Waurn Ponds Cement Mill. This provided the company with more efficient power consumption. Read more about the BCSC airslide conveyor project.

Blue Circle Southern Cement airslide conveyor system project

Do you need help conveying bulk materials like cement, asphalt and grains with airslide conveyor systems? We design, manufacture and install airslide conveyor systems to fit any situation. Talk to us and send us a message today.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541