See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Thursday, November 10, 2022

We are pleased to announce that Vortex Australia has appointed Pneuvay Engineering as its sole agent.

US-based Vortex has chosen Pneuvay as their local industry expert to assist with supply of their slide gates, diverters and valves. Their quality specialised components are used to handle bulk powders in gravity flow, dilute phase or dense pneumatic conveying systems.

Vortex Australia agent officially Pneuvay Engineering

Vortex Australia is able to supply its complete range of components via Pneuvay. Their components fit into two broad groups: valves and spouts. Their valves range is split into three categories: gates, diverters and valves.

Vortex slide gates are used for controlling the release of bulk powders from containers such as hoppers, bins, silos or conveyors. These gates comprise a frame housing a sliding plate which allows or prevents the flow of materials. The slide plate can be operated by use of manual, pneumatic, electric, or hydraulic mechanisms.

We supply the following Vortex slide gates:

Vortex diverters are ideal for diverting bulk powders in gravity flow, dilute phase or dense phase pneumatic conveying systems. They cover heavy duty applications where they can be used to divert abrasive materials from one source to two or three destinations.

We supply the following Vortex diverters:

Vortex valves are specifically made to handle bulk powders in systems that use gravity discharge. They are used to manage free-flowing material from bins, bulk bags, chutes and hoppers.

We supply the following Vortex valves:

Also referred to as loading chutes, Vortex loading spouts facilitate rapid, consistent material transfer while loading dry powders into open or enclosed containers, such as trucks, railcars, ships and storage areas.

We supply the following Vortex Loading Spouts:

Each Vortex component is manufactured when ordered, as they must be customised to suit the specific pneumatic conveying and bulk powder handling system. This custom build is a major advantage Vortex has over competing manufacturers. As a result, it is not possible for Pneuvay or Vortex to hold these components on hand. Generally, the lead time to supply a given component is from nine (9) to fourteen (14) weeks from order. They are made in Kansas in the US, and shipped using ex-works.

Vortex Australia components include slide gates, diverters, valves and loading spouts

Since starting up in 1982, Pneuvay has always sourced the slide gates, diverters or valves to be embedded in any pneumatic conveying system we would build. Our focus has always been on providing integrated pneumatic conveying solutions wherever possible. Importing and integrating these specialised components with the pneumatic conveying systems we design and build makes for optimal production flow.

Over the years we tried out several manufacturers. In 2006 we contacted Vortex and started using their components. They had been operating since 1977 and were well-established in making specialised components for bulk powder pneumatic conveying systems. Their slide gates, diverters and valves were known to be efficient in operation, have long-term reliability, and help maintain dust-free environments. Over time it became clear that their components were top quality and their service delivery was excellent.

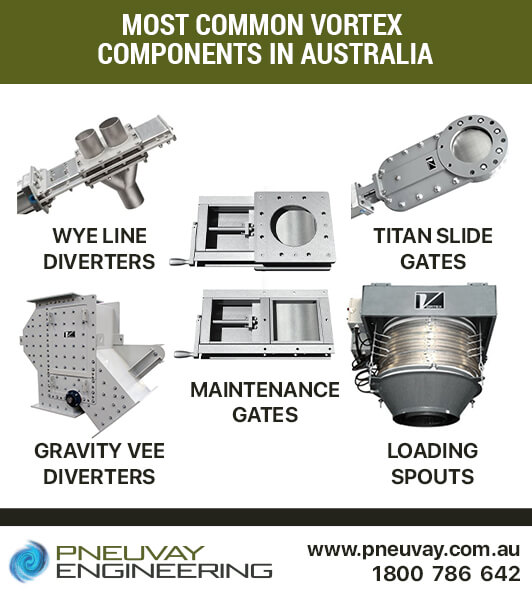

In 2010 we decided to settle on Vortex as our sole supplier and become experts on the supply of their components. Paul Malcolm, General Manager of Sales and Engineering at Pneuvay, said "The most popular Vortex components we supply are the Wye line diverters, Titan Slide Gates, Gravity Vee Diverters, Maintenance Gates and Loading Spouts. It is hard to narrow this down to such a small set, as there is demand for all Vortex components. Their popularity in Australia, however, is due to them being those most commonly used in Australian industrial applications.

Most common Vortex components in Australia

In 2016, Michael Francis, our Managing Director of Pneuvay at that time, visited the European division of Vortex at Darlington in the United Kingdom. Travis Young from Vortex said how they "really appreciate the kind of technical partnership we’ve enjoyed with Pneuvay over the past decade." said Travis”.

As our trading relationship deepened, we contacted Vortex about taking the next step and becoming their sole agent for Australia. It did not take long for Pneuvay Engineering and Vortex to make this partnership official, and now we are delighted and proud to announce it in Australia.

Michael Choo , General Manager of Operations at Pneuvay said, "We have had a longstanding relationship with Vortex Australia that dates back to 2006. To become the sole agent is the further development of an important partnership that benefits Australian industry as well as both companies. It enables local industry to better source and secure the Vortex slide gates, diverters and valves."

As the market leader of Australian pneumatic conveying companies, Pneuvay is able to offer expert advice when supplying Vortex components for use in pneumatic conveying systems used to transfer bulk powders. If you have any questions or need help regarding Vortex components, feel free to call on 1300721458 or contact us. You can even send us a message via our Facebook page if you like.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541