See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Monday, September 30, 2019

Trim removal systems collect and convey (pneumatically) film and foil off cuts generated by several major production processes. They help manufacturers save money, optimise productivity, increase recycling and improve safety.

The trim is collected using a suction process, and conveyed through a purpose-built pipework system. The pipework transports the trim using a high speed air stream. Blowers are used to drive the air stream and deliver the trim to compactors, horizontal balers or large mobile storage containers. The trim is then prepared for disposal or recycling. These systems are carefully integrated into the factory to maximise operation and maintainability.

Two main types of systems are used to collect and pneumatically convey trim to a waste collection point.

This type of trim removal system uses a venturi component to transport a continuous ribbon of trim.

The other type of trim removal system uses a cutter to convert the trim into high density, low volume confetti while transporting it.

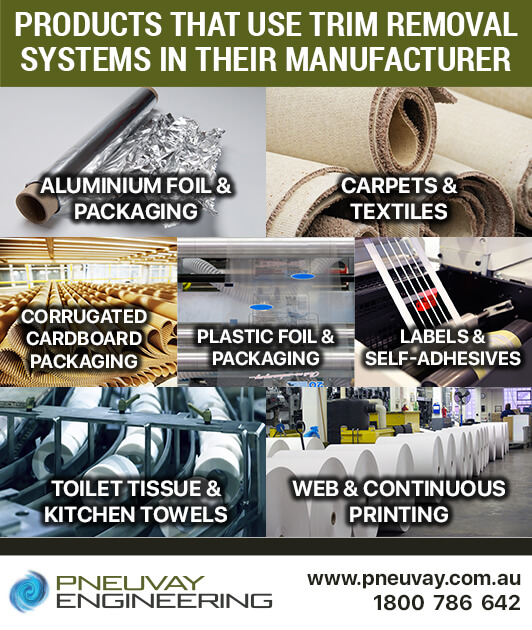

Trim removal systems are mainly used in machinery for converting (rewinders and slitters), film and foil (cast lines) production and paper manufacturing. They are used in the industrial production of the following products:

Products that use trim removal systems in their manufacturer

There are several factors to consider when selecting the type of trim removal system that will best suit your needs. A venturi trim removal system is generally considered the most economical, however, the best long-term return can come from using a cutter trim removal system. We have listed below the major factors that will help you choose what is the best type for your situation.

Venturi trim removal systems come at a much lower installed cost compared to cutters. They are ideal for companies that want to save on labor and maintenance costs but do not have enough capital to invest in a cutter system.

Cutters cost substantially more to install but provide greater return on investment over time. These systems require fewer loads for disposal or recycling, as their waste volume is greatly reduced. Cutters also use much less energy than venturis and operate at lower cost.

Venturis have fewer components, are simpler, and take less time to install. Cutters require more consideration in design and greater effort to install. A venturi trim handling solution can be temporarily installed quickly, while a cutter is designed and installed.

Venturis simply transport the trim to the waste collection point as a continuous ribbon. They do not process the trim in any way. Cutters process the trim to confetti.

Both venturi and cutter trim removal systems are great for continuous and high-speed trim production lines.

Cutters are best when you need to convey trim over long distances or through several bends in the pipework; long distances with turning and twisting pipework are no problem. Venturis are not effective when transporting trim over long distances or with pipework that has three or more bends.

Venturis require much more energy to transport trim than cutters. More production lines will make the system energy-inefficient. Venturis also require a large footprint on the factory floor. Cutters are energy-efficient and centralised to service several production lines, requiring a relatively small factory footprint.

Bale waste from a venturi is inefficient compared to cutters. As the trim is in a continuous ribbon rather than confetti, the bales are looser and bulkier. Cutters process trim into small pieces that are easily compacted into low volume, high density bales.

Venturis vs cutters trim removal system

For more than 30 years Pneuvay has been providing help on venturis vs cutters when developing the best trim removal systems for companies. We have experience in a broad range of Australian industries, designing and installing trim removal systems that have:

If you have any questions in relation to trim removal systems, feel free to call us on 1300721458 or send us a message via our Pneuvay website contact page or Pneuvay Facebook page.

Get social with us and see the latest news items from:

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541