See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, April 28, 2021

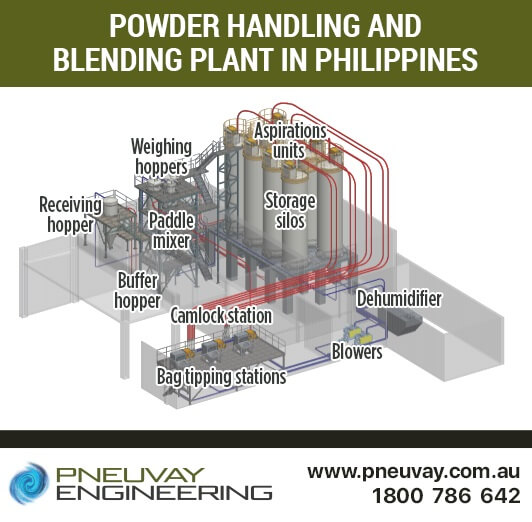

Pneuvay is proud to showcase a large-scale chocolate milk powder handling and blending plant recently completed in the Philippines by our engineering group (Pneu Powder Systems).

Our group designed and built this enormous system integration project in 12 months. The project was successfully delivered in October last year.

It was handed over on time and on budget, despite much of the project timeline being affected by the pandemic. Quite an achievement!

The scope of work involved the supply and integration of equipment and components that:

Three types of pneumatic conveying are used to transfer materials throughout the plant:

The chocolate milk powder plant belongs to a large regional manufacturer of marketable high quality and economical food products. It upholds the highest standards in its food manufacturing and prides itself on continuous improvement. The detailed case study we have made on their new plant demonstrates our ability to deliver on projects of this size and complexity.

The showcase has the following sections:

Read on and enjoy.

Case study on chocolate milk powder handling and blending plant in the Philippines

Our engineering group (Pneu Powder Systems) was awarded the tender to design and build the chocolate milk powder handling and blending plant in the Philippines primarily for its:

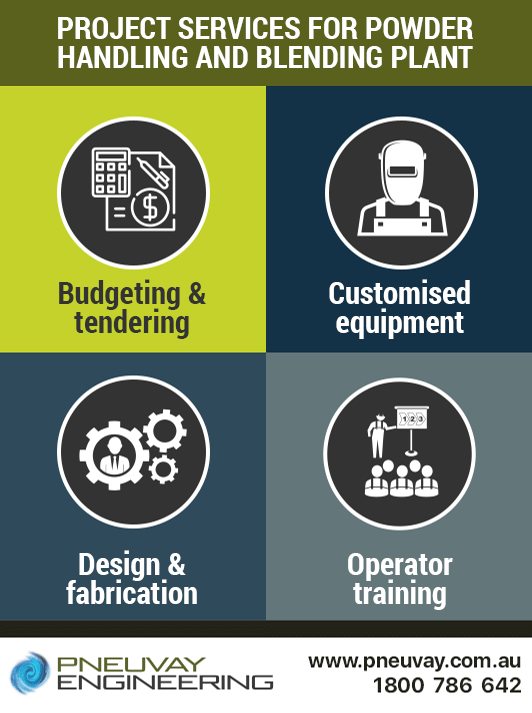

Our total system approach meant that many of the project services we provide could be used. This comprehensive combination of services ensured the project was a complete success, being delivered on time and on budget.

Our experience in helping uncover concealed factors within and between the stages of a large food processing plant was invaluable when developing the project proposal. We refined an alternative solution that better optimised processing and added greater value without increasing costs. Further, as part of the proposal, we provided budgeting estimates for items such as ongoing maintenance and servicing. This allowed the proposed processing plant to be evaluated as a total cost over time, rather than just a setup cost.

The powder handling and blending systems needed to be designed and installed into existing factory buildings and structures. Our engineering team spent six months designing and planning the sophisticated food processing system.

The team’s extensive experience in developing these systems and the pneumatic conveying required to transfer these materials made sure their plan delivered on:

Several pieces of custom equipment were required to be designed and fabricated. Our highly skilled engineers developed best-fit solutions for processes such as:

Our team (Pneu Powders Systems) developed and supplied training for the operators when the commissioning of the plant was completed. User manuals for the equipment operation were made and supplied to use for reference during ongoing plant operation.

Project services delivered for chocolate milk powder handling and blending plant

This example of this powder handling and blending plant project is detailed and broken into several major sections including:

Pneuvay, as part of the Pneu Powders Systems group, operates as a market leader in system integration for powder handling and blending plants. Our coverage area stretches from the Asia-Pacific through to the Middle East and includes Australia and New Zealand.

We provide solutions to large and small food producers looking to:

Our group is specialised in system integration for a wide range of food products such as:

This example of a powder handling and blending plant is the latest in a series of case studies from our engineering group. It clearly demonstrates our experience as a market leader in powder-based food processing plants. Our joining with the (Pneu Powder Systems) engineering group allows us to focus on servicing Australia and New Zealand as well as the Asia-Pacific and Middle East.

Case studies on other projects by the engineering group include:

Feel free to contact us if you have any questions in relation to the design and installation of a powder handling and blending plant. Our engineers are happy to help and provide the assistance you need. Call on 1300721458, contact us with our online form or message us on our Facebook page.

Get social with us and see the latest news items from:

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541