See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, October 20, 2021

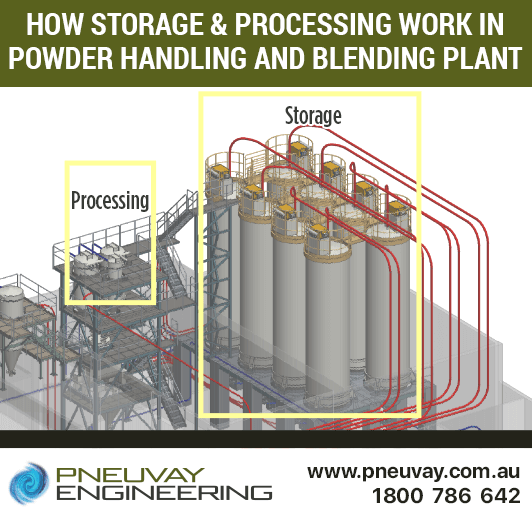

The next part of our large chocolate milk powder and blending plant case study details how the storage and processing stages work. We articulate how the raw materials (processed sugar, creamer, cacao, whey and milk powder) are transported and stored within a large eight-silo system. We then describe how these raw materials are processed by being weighed, batched and prepared for the blending stage.

How the storage and processing stages work in powder handling and blending plant

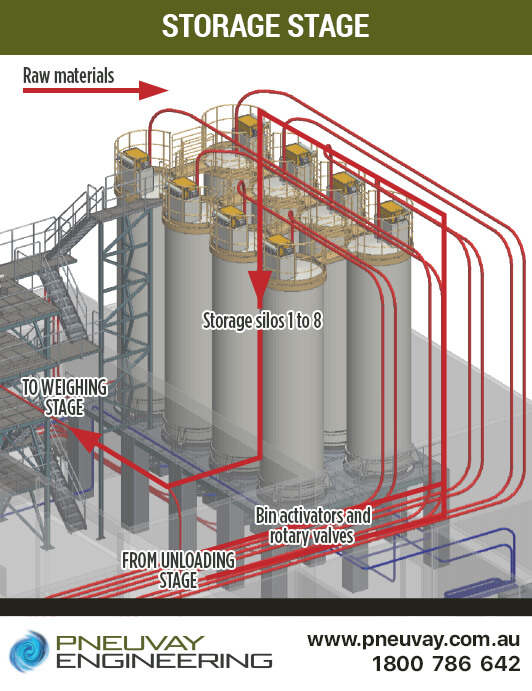

The storage stage receives raw material from the unloading stage. It then transfers the material to the processing stage for weighing. This is a large facility comprising eight 304 stainless steel silos, each with a capacity of 20 tonnes. Silos 1 to 4 are filled using bag tipping station 1, while silos 5 to 8 are filled using bag tipping station 2. The pipework feeding the raw materials into the silos is connected using Toyo spring hoses. Filling the silos from bag tipping stations 1 and 2 is a manual process.

The raw materials stored in these silos are:

Aspiration units for dust collecting in and around the storage area are mounted to the top of each of the silos. Made of 316 stainless steel, they have a jet pulsed cleaning system. These aspirators are of modular component design, making them easy to dismantle for maintenance and inspection. They use Snaptex filters, which are easily released and changed.

At the bottom of the silos are bin activators. These are attached to rotary valves with BFM flexible connectors and spigots. The bin activators, made of 304 stainless steel, have the following features:

The rotary valves are used to dispense raw materials from the storage silos into the pipework connecting to the weighing hoppers. These drop-through sanitary model rotary valves are demountable and made in 304 stainless steel, with heavy duty outboard bearings and ANSI flanges. They are air-purged and shaft-sealed, use a chain drive for their gearboxes, and are custom-made by our engineering group (Pneu Powder Systems).

From the pictures and detailed descriptions of the silos and connected equipment you can see the storage stage is central to the operation of the plant.

Check out the following:

Storage stage of powder handling and blending plant

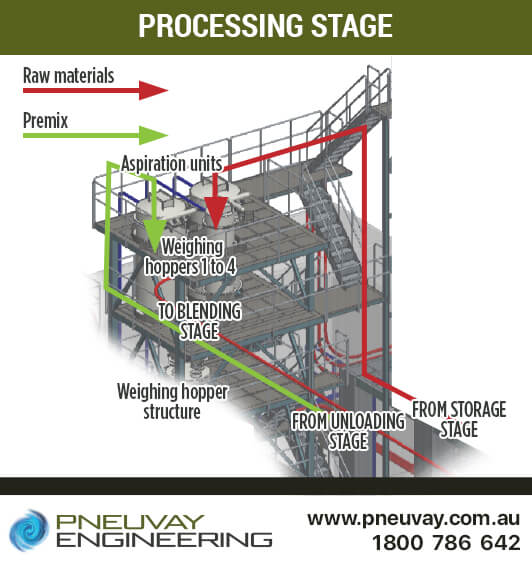

The processing stage receives raw material from the storage stage plus minor ingredients from the unloading stage, for weighing and dispensing into the blending stage. All materials are fed into four weighing hoppers, with 316 stainless steel three-inch pipes using lean phase vacuum conveying from nearby vacuum pumps. Raw materials, which have been sifted and filtered using metal separators, are fed in from silos 1 to 8. Sifted minor ingredients are fed in from bag tipping station 3. Grinding of the materials is not required as they are supplied to the plant ready for blending.

Minor ingredients from bag tipping 3 are conveyed to weighing hopper 1, then filled using a manual process. Whey powder and processed sugar from silos 1 to 4 are conveyed to weighing hopper 2. Milk powder and creamer from silos 5 to 7 are similarly conveyed to hopper 3. Cocoa from silo 8 is conveyed to weighing hopper 4. The filling of hoppers 2 to 4 is managed from the control room.

The weighing hoppers are configured as follows:

Only one pipeline from a silo can be used to fill a given weighing hopper. Weighing hopper 2 can, therefore, receive whey powder or processed sugar, but not both substances at the same time. All four hoppers, however, can be filled with a given material at the same time. The pipelines are connected to the hoppers with Toyo spring hoses. The four weighing hoppers dispense all materials into the discharge chute and the paddle mixer below in the blending stage.

Aspiration units made of 304 stainless steel are fixed to the top of the weighing hoppers. Used to collect dust in the weighing hopper area, they are straightforward to inspect and maintain. Similar to the units used in the storage silo area they use jet pulsing for cleaning, and easy-to-use Snaptex filters.

We have a set of pictures showing the equipment used in the processing stage. Included is a detailed description of what each piece of equipment does and how it integrates into the plant.

Check out the following:

Processing stage of powder handling and blending plant

This case study on the chocolate milk powder handling and blending plant project is extensive and made up of several major sections including:

A list of other food processing plants case studies our engineering group has completed.

Pneuvay, as part of the Pneu Powders Systems group, is a market leader in storage and processing systems in powder handling and blending plants. Our expertise in these specialised engineering services is available locally in Australia and New Zealand. Via Pneu Powders, however, we are able to service all regions throughout the Asia-Pacific and Middle East. Contact us if you need expertise in storage and processing systems for powder handling and blending plants. Call on 1300721458, contact us with our online form or message us on our Facebook page.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541