See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Thursday, June 28, 2018

With our engineering group focusing on food processing plants, we wish to showcase two interesting examples where we have installed or upgraded granular and powder bulk storage systems.

Granular and powder bulk storage systems are often complex and challenging. Each system usually has a specific set of requirements, with many unique to the particular situation. Expert design and extensive experience in storage silos, hoppers and other integrated components are essential in developing a best fit solution. Further, rigorous project management is needed to execute and deliver these systems with minimal disruption to the surrounding plant.

Storage systems connect the 'unloading' and 'processing' stages within a food processing plant. They are used to store raw materials and feed production via pneumatically conveying. Some plants output a granular or powder material as a finished product such as flour. In these cases, a bulk storage system is required to feed the 'bulk loading' process.

These systems require an awareness and knowledge of issues that arise from loading, feeding, silos, hoppers, bins and bulk containers. However, the bulk storage systems examples we are showcasing demonstrate there are often specific issues that make each project challenging in their own unique way.

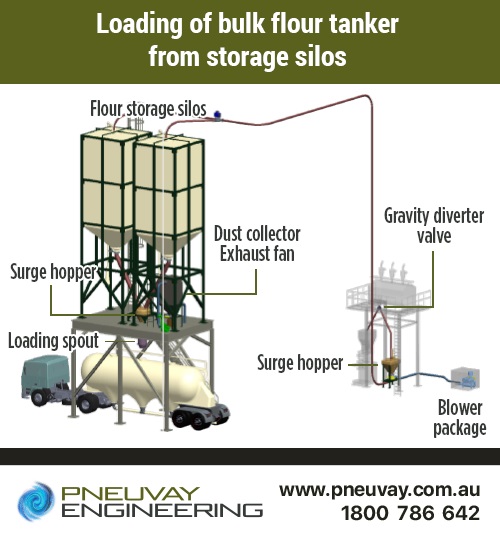

A medium-sized flour mill required a cost-effective powder bulk storage system to allow for the loading of bulk flour tankers. The solution included two flexible silos to act as buffer storage for flour transferred from the production area. A gravity diverter valve was installed above the bag packing system to allow for the pneumatic conveying of flour to fill up each of the 30-tonne silos. A rotary valve system extracts the flour from the silos to a self-retractable loading spout attached to the base of the silo system. The spout was integrated to a dust collector system to allow the loading of bulk flour tankers without any dust emission.

The flexible silos were made from a high strength polyester fabric from TREVIRA. This is an extremely durable, fire-resistant and tough non-toxic fabric. The silos are dust-proof but slightly permeable to air. This avoids condensation forming on the silo walls and ensures that flour agglomeration does not occur. Flexible silos use a light and strong galvanised steel frame that is easy to assemble and install. The flour is pneumatically fed into the silo, where it descends by gravity. The vertical silo walls allow the flour to discharge smoothly from the bottom to a loading spout, and is extracted using either rotary valve or screw conveyor.

Flexible silos are inexpensive, modular and provide excellent vertical storage for powders like flour, corn starch, tapioca flour and sugar. To maximise their performance, it is recommended they be integrated with an air conditioning system to eliminate the possibility of condensation, and therefore prevent product agglomeration. These silos can supplied in standard sizes or be customised to fit into a specific location within a plant. Our engineering group has installed many flexible silos as part of a bulk storage system in food processing plants throughout South-East Asia.

The systems and components used in loading a bulk flour tanker from storage silos example is as follows:

Example of a loading of bulk flour tanker from storage silos

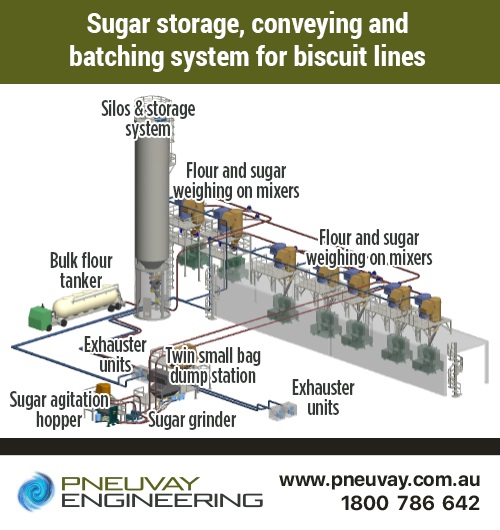

Our engineering group has successfully installed many bulk storage systems in biscuit manufacturing plants. The storage system must be integrated into several distinct processes and support nearby complementary systems in the processing stage. The processes and systems that the storage system integrates or complements with include:

In this example, the flour is brought into the biscuit manufacturing plants via bulk flour tankers and is fed to the outdoor bulk storage silos. The raw sugar is brought into the plant via small bags (25 or 50 kgs) or bulk bags (500 to 1500 kgs) and debagged at the twin bag dump station. An operator tips the raw sugar from the bags to a pneumatic conveyor that transports it to the grinder. This is where the raw crystalline sugar is ground into fine sugar or icing sugar. The fine sugar is then pneumatically conveyed to the weighing stations on each mixer and discharged in the mixer accordingly. The receiving hopper or weighing hopper discharges the sugar to the mixer using 'loss-in weight' or 'gain-in weight' methods.

It was vital that the outdoor bulk storage silo system be designed and installed so that it did not cause any disruption to the complementary systems. The bulk storage system was required to be in close close proximity used to systems used to process the raw sugar and blend the flour and fine sugar.

The process of dispensing and dosing of palm oil, palm olein and rapeseed oil to the flour and fine sugar involve a level of high precision. We ensure systems used to transfer oil-based products like these are metered and dosed accurately, as required by the project specifications. The transfer of the oil-based products is done by positive displacement pumps; however a centrifugal pump could have been used.

Stringent safety protection requirements need to be met when handling flour and especially fine sugar. Fine sugar has a high severity when ignited in a dust explosion (high Kst value) and is capable of unleashing powerful explosions. Compliance to European ATEX and NFPN standards is mandatory. Our engineering group has extensive experience in designing powder handling and pneumatic conveying systems to be in fully compliance with ATEX and NFPA safety standards. We work with many European ATEX certification companies that independently confirm our installed systems are fully compliant with ATEX and NFPA standards.

The systems and components used in the sugar storage, conveying and batching system for biscuit manufacturing plant example are as follows:

Example of a sugar storage, conveying and batching

system for biscuit manufacturing plant

Pneuvay is a leading system integrator for granular and powder bulk storage systems in food processing plants. We service many food producers in the Asia-Pacific and Middle East and are expanding into the Australian industry. We provide best fit solutions for installing or upgrading various stages, systems and accessories when developing food processing plants.

If you have any questions on granular and powder bulk storage systems for a specific food processing plant, feel free to call on 1300721458 or contact us.

More information on granular and powder materials.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541