See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Thursday, August 29, 2024

Centrifugal and regenerative blowers are widely used in many industrial processes. Both types look similar, but there are distinct differences of which you need to be aware.

Centrifugal blowers maintain a low pressure while delivering a high flow of air. They’re ideal when a large volume of air is required without high pressure. To maintain these airflow levels centrifugal blowers operate at their maximum. They are generally built as standalone machines that are not customised with accessories.

Due to the way they’re designed, regenerative blowers are able to span a range of performance flow rates and pressure levels. These types of blowers can operate effectively and efficiently for most applications where centrifugal blowers are used. Further, these blowers generally have accessories to increase noise reduction or improve filtration.

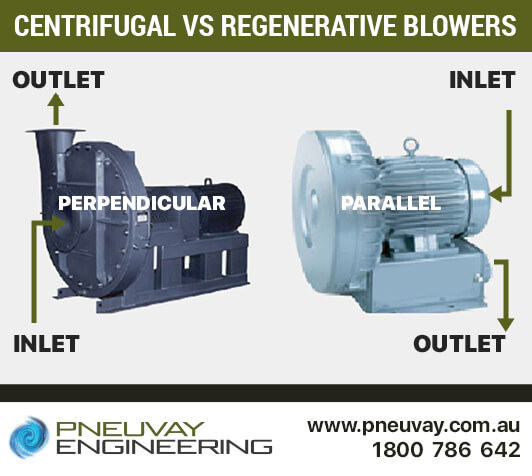

Distinct differences are clearly seen in the configuration of these two blowers in the comparative illustration. Centrifugal blowers are configured so the inlet and outlet are perpendicular. The inlet feeds air into the centre of the impeller while the outlet stays in tangential to the rotation of the impeller. On the other hand, regenerative blowers have parallel inlets and outlets that are positioned perpendicular to the rotation of the impeller.

Centrifugal blowers vs regenerative blowers

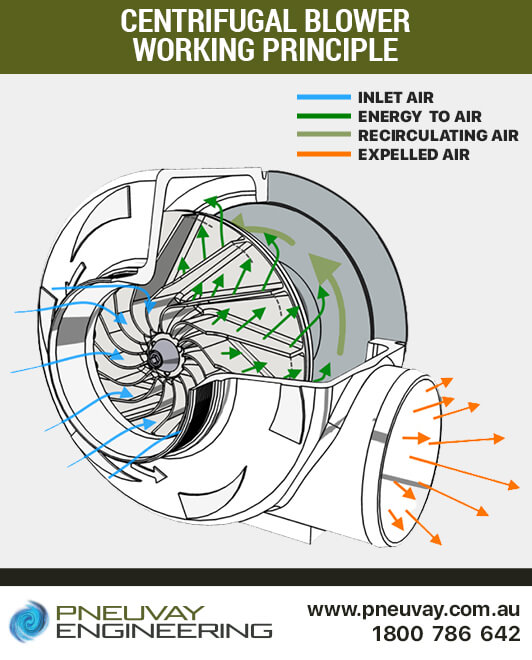

Centrifugal blowers allow air to enter through the centre of the rotating impeller. A number of fixed vanes acts as paddles to push the air to the outlet. Through centrifugal action air is forced to the impeller and housing, where it is discharged through the outlet as a steady stream. This creates negative pressure at the central hub that sucks in more air.

Centrifugal blower working principle

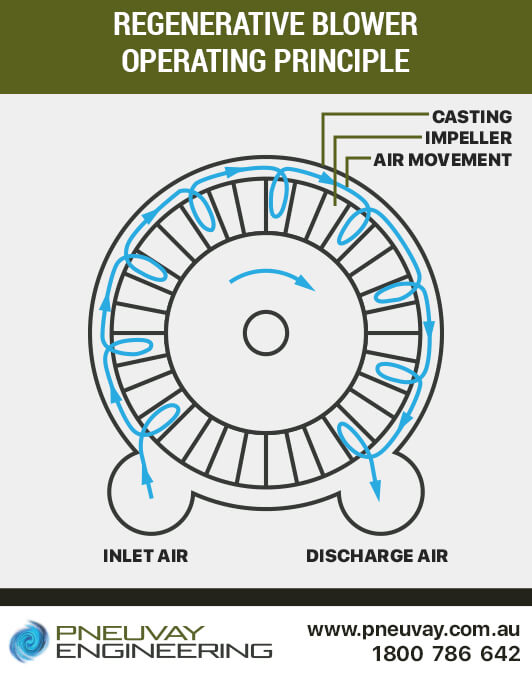

Unlike centrifugal blowers, regenerative blowers are designed to work in a different manner. They have an impeller that spins within a housing compartment that contains both an inboard and outboard channel. An alternate name for this type of machine is a side channel blower. The moment the impeller spins past the intake import, air is drawn in and is trapped between its impeller blades. As it continues to spin, air is pushed both inward and outward through both channels. This continues until the impeller stops rotating. As a result, regenerative blowers can act as either pressure or vacuum blowers.

Regenerative blower operating principle

Generally, centrifugal blowers require more frequent maintenance in comparison to regenerative blowers. This is because there are several components, the bearings in particular, requiring lubrication. Regenerative blowers are designed to be contact-free, making them virtually maintenance-free. They can operate up to 40,000 hours without needing to be serviced.

Regenerative blowers generate a low level of noise when operating, making them ideal when noise-sensitivity is an issue.

Talk to us about which of our centrifugal blowers with low noise levels are ideal for your specific requirement.

As a general rule centrifugal blowers are considered low pressure high flow. while regenerative blowers are high pressure low flow. This makes each ideal for specific industrial applications.

Centrifugal blowers work for applications where low pressure air is required for some specific purpose. An example is when passing large air volumes in a furnace to fuel combustion. The required air volume is large, but does not need to be under pressure.

Major specific applications include:

Types of equipment and systems that use centrifugal blowers include:

Machinery that uses centrifugal blowers includes:

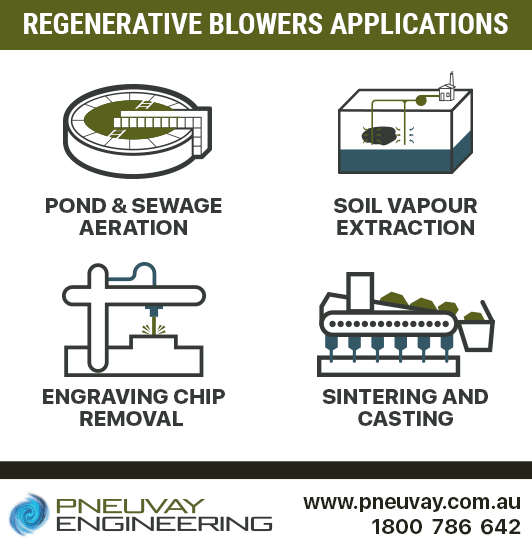

Regenerative blowers are generally used when a large volume of air at high pressure is needed for the specific application. They are also used in situations that involve flammable gas, or have some hazardous or heavy duty aspect to the process.

Major specific applications include:

Types of equipment and systems that use regenerative blowers include:

Machinery that uses regenerative blowers includes:

Regenerative blower applications

Pneuvay Engineering has extensive experience in distributing and maintaining centrifugal blowers and regenerative blowers. We are the primary Australian sales contact for Spencer Turbine blowers. Call us today at 1300721458 or send us a message regarding centrifugal and regenerative blowers.

Get social with us and see the latest news items from:

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541