See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, May 17, 2023

There are many misconceptions in the pneumatic conveying of dry bulk granular materials such as how pellet transfer speed works. These misapprehensions apply specifically to the pneumatic conveying of similar materials, including:

One major misconception is how air pressure relates to transfer speed.

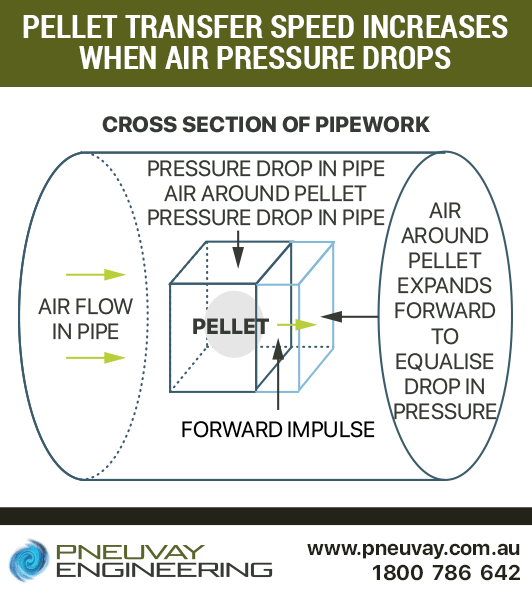

The idea that transfer speed rises as system pressure drops is counterintuitive, but it really does occur when pneumatic conveying pellets. When piping system pressure decreases, the speed of pellets in the pipework increases. You have to look carefully to work out why this occurs.

Did you know pellet transfer speed increases when air pressure decreases in pneumatic conveying?

With steady temperature levels, a given cross-section of the piping system near the entry point has a fixed volume of air around the pellets at a specified pressure. As the air moves downstream the cross-section of the piping system near the exit point would contain the same amount of air, but at lower pressure due to a loss in system pressure. System pressure loss occurs naturally from frictional losses as pellets come into contact with piping walls.

As the volume of air is fixed by the cross-section of the piping system, the drop in pressure makes the air expand in the direction of the air flow. This creates an instantaneous 'push' to any pellets in the region of the pressure drop and generates an increase in their speed. A short section of piping may not experience a significant increase in transfer speed. However, pressure decreases that occur over longer sections of piping will accumulate and produce a noticeable increase in pellet transfer speed.

Why pellet transfer speed increases when air pressure drops

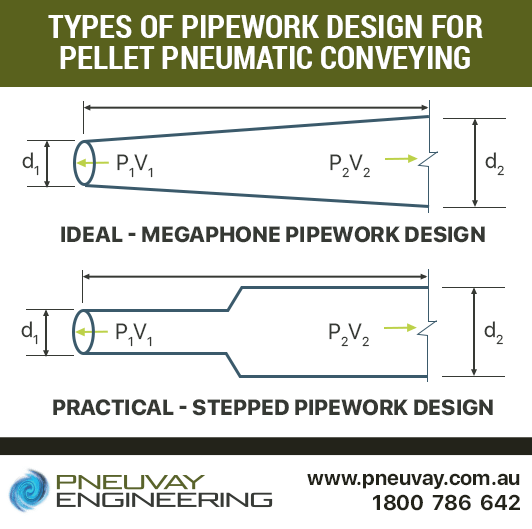

The ideal way to mitigate the effect is to shape the pipework in the form of a megaphone. Along the pipework length the bore diameter grows gradually and incrementally from small to a maximum size. This, however, is not practical or feasible. The best solution is accomplished through increasing the pipe bore by a fixed diameter, in sections, in a series of steps along the pipework.

Over lengthy pipework, the pipe bore diameter may be required to be increased by seven to 10 millimetres (three to four inches) in the final third length of the system. This stepping of pipe diameter allows for the air to expand vertically to the air flow as pressure drops, and obviates much of the instantaneous 'push' horizontally. The increase in volume in that given cross-section of the piping system will be enough to keep the transfer speed constant and minimise pellet transport issues like angel hair generation.

Read up on minimising pellet pneumatic conveying system problems like streamers and angel hair.

Pipework design for pellet pneumatic conveying

An industry leader in the design and manufacture of bespoke pneumatic conveying systems, Pneuvay is ideally placed to help you with your pellet transfer requirements. Our clients include many large, major manufacturers that have turned to us for the design and successful provision of best fit and turnkey solutions for:

If you need help with pellet pneumatic conveying systems or assistance is solving pellet pneumatic conveying system problems, feel free to call on 1300721458 or contact us. You can even send us a message via our Facebook page if you like.

Get social with us and see the latest news items from:

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541