See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Tuesday, July 31, 2018

As part of our engineering group's focus on food processing plants, we will showcase two impressive example integrations of powder handling systems. System integration within and between the various operational stages of these plants is demanding and complicated engineering work. These projects have general requirements that are typical for granular and powder food processing plants; however, they each have specific requirements and settings that make them unique and challenging when designing and installing the best fit solution.

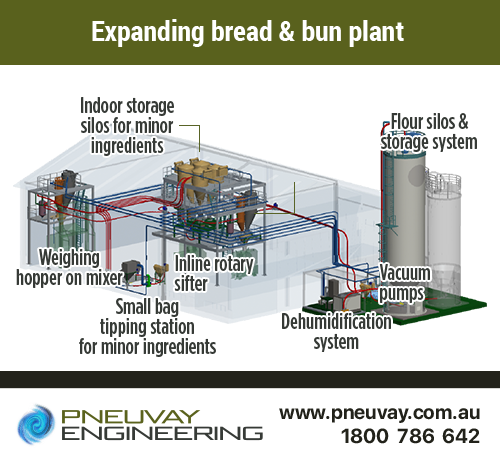

A major bread and bun manufacturing plant wanted to significantly expand its production capacity. They required the expansion to production to remain within its existing building infrastructure. Further, they did not want their production to be disrupted while the expansion was being implemented. Finally, the new systems are expected to operate continuously (24x7).

This type of project is ideal for our systems integrator engineering group and has a typical set of project requirements; however, a number of specific circumstances made for a challenging design and installation process. Our extensive industrial expertise and experience enabled us to overcome these challenges and deliver a best-fit solution.

State-of-art powder handling systems needed to be carefully designed and installed to fit within the various confined spaces of the existing building. Further, the new system had to be integrated at several major points into the existing powder handling system. These two factors made the installation very difficult to implement as the existing production process was not to be disrupted in anyway.

The increase in powder handling systems more than doubled the volume of flour needed for the processing plant. As a result, an additional external storage silo was required to be designed and installed. The new 50 tonnes capacity flour silo was installed next to the existing 30 tonne silo. To maximise the investment and reduce duplication, the existing discharging system was modified so it could be used for both external storage silos.

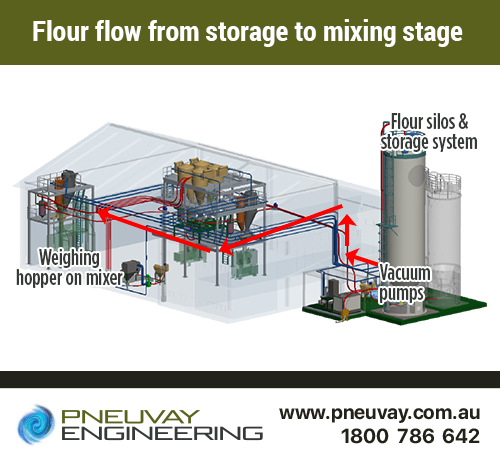

The major ingredient of bread and buns at this plant is flour. The flour is transferred from the silos in the storage stage for weighing in the processing stage. The transfer is done using lean phase vacuum conveying. This is a form of pneumatic conveying used to transport fine powders. Once the flour is weighed out by weighing hoppers, it is discharged to mixers located underneath and ready for the mixing stage.

Flour flow from storage to mixing stage

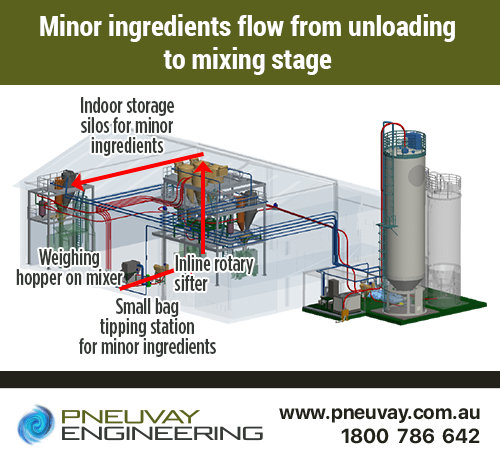

The minor ingredients of the bread and buns are sugar, salt and gluten. These materials come to the plant in 25kg bags, which are manually bag-tipped. The sugar, salt and gluten are then sifted inline and transferred for storage in several separate indoor storage silos.

Minor ingredients flow from unloading to mixing stage

A customised Scada Control System with a high precision micro dossier centrally weighs each of the minor ingredients based on pre-programmed recipes. The minor ingredients are then combined and transferred to weighing hoppers where the combined weight is counter checked if within a preset fine tolerance. If the tolerance is not met, the Scada System will alert high level production personnel to determine whether to accept or reject the batch. Combined minor ingredients that are within weight tolerance are then discharged to mixers located underneath and ready to be mixed with the flour in the mixing stage.

The dehumidification system provides air-conditioning around the indoor storage silos and weighing hoppers. To maximise the investment, this system is integrated to supply dry cool air for the transport of the minor ingredients around the plant. It drives the pneumatic conveying via lean phase vacuum conveying from the:

Example of expanding bread and bun plant

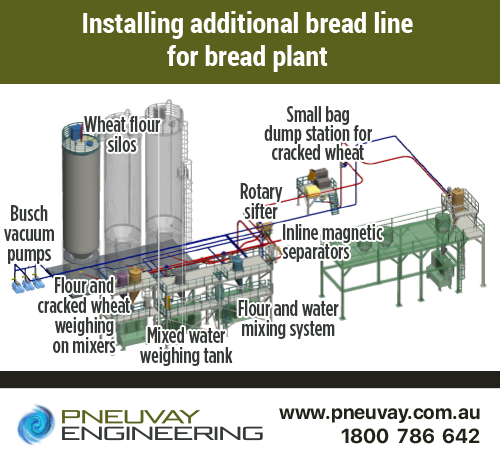

The expansion of production capacity by adding a new bread line inside an existing large bread plant was required. At a glance the solution seemed simple, as it appeared we could integrate additional powder handling systems for the flour to the existing storage silo system. When, however, the investigation of the plant was completed, an unseen complication arose that would make the best fit solution much more complex than first anticipated.

The powder handling system for the flour was not only expected to integrate with the storage silo system but also the existing minor ingredient system. This would eliminate having to install another minor ingredient system and was vital to keep the project within budget.

This requirement caused a significant complication when developing a best fit solution and resulted adding to the project scope. It was discovered that the existing minor ingredient handling system was "under"-designed and not able to cope with the increased throughput of the plant with the new second bread line. We overcame this problem by being able to develop a plan to upgrade the existing system, despite that system being designed and installed by another international supplier.

The existing and new bread lines would produce 12,000 loaves of white sandwich bread. The production downtime allowed for the implementation of the project was a maximum of two days. The complete solution included:

We first developed a solution to modify the flour silo storage and flour handling system to best integrate into the new second bread line. We had to work out the best way to expand the storage and discharge capacity that maximised the use of the existing flour line, two existing storage silos and its discharge system. The solution was to install one additional storage silo and modify the existing discharge system. The modifications to the discharge system would allow the two bread lines to draw the flour simultaneously from the other two existing silos. This solution greatly improved the output of the existing breadline.

In order to use the existing minor ingredients system we had to upgrade it to make it suitable for the new level of plant output. With some creative engineering we were able to double the dosing and weighing of the minor ingredients system. Further, we are able to meet another important production requirement, which was to ensure a smooth transfer of material.

Improvements were also made to the outdated water mixing used for the existing bread line so it could attain the desired temperature. We combined our modular water mixing unit with a mixed water weighing for each of the mixers. This configuration was able to supply all the required water metering needs of the system and get the water to the desired temperature for each production mixing cycle.

Systems and components include:

If you have any questions on granular and powder handling systems for a specific food processing plant, feel free to call on 1300721458 or contact us.

More information on granular and powder materials.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541