See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Friday, August 31, 2018

Building or upgrading industrial bakeries often involves the integration of pneumatic conveying into several powder handling systems. These plants are sophisticated and complex. They involve the storage, handling and processing of flour and minor (powder) ingredients and then mix them with water.

Our engineering group has a major strength in bakeries. We showcase two interesting example bakery system integrations. These projects have general requirements that are typical for these types of plants. Make makes these projects challenging is finding out what the specific requirements. These alway make each project unique and challenging when designing and installing the best fit solution.

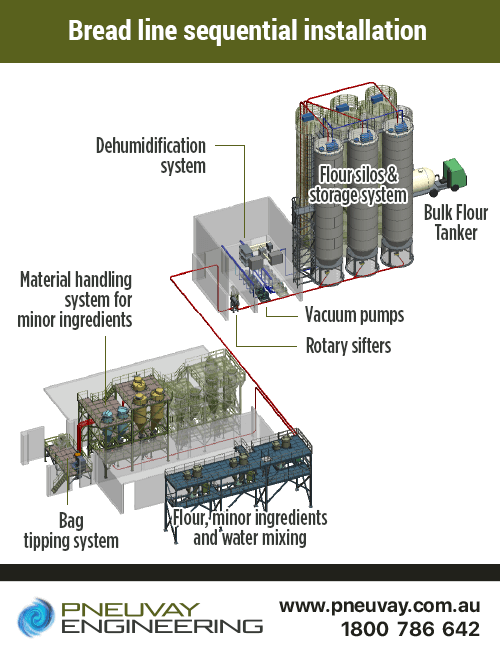

An industrial bakery required the sequentially installation of a bread line within their existing building. Each new production line was to be added every two years. The bakery used a highly sophisticated material handling system that processed several types of flour and minor ingredients, and had many demanding technical and production requirements. Careful investigation, design and planning were required to ensure these repeated additions were feasible and sustainable.

Flour, delivered by bulk trucks from nearby flour mills, is pre-sifted before transferring to specific silos. The pipes used to unload the trucks are physically labeled and equipped with pre-programmed control switches to ensure the correct flour is fed to the correct silo. Each silo is mounted on several high precision triple point weighing load cells. These enable the silo flour inventory to be physically shown at the silo base. The weight of flour in the silo is also remotely transferred to a human/machine interface (HMI) so that it can be monitored by ordering personnel.

The flour from the silos is sifted again using a heavy duty inline vacuum sifter and then passed through a magnetic separator by a negative pneumatic conveying (vacuum) conveying system. It is then weighed at the weighing hopper positioned on top of the mixer.

The raw materials for the minor ingredients come in small and bulk bags and are fed into the plant by bag tipping units. The ingredients go through an inline sifter and an inline magnetic separator before they are conveyed to indoor storage silos. Each type of minor ingredient is stored separately in an indoor storage silo. The number of silos is dependent on the number of types of ingredients.

Some of the minor ingredients are hydroscopic in nature so a dehumidification system is used to air condition the indoor storage area. This prevents caking or agglomeration of the hydroscopic materials. The same dehumidification system is used to provide cool dry air for pneumatic conveying. The minor ingredients are pre-weighed centrally, then combined and vacuum conveyed to another weighing hopper. The batch is of pre-weighed ingredients is checked to ensure it is within tolerance.

The equipment used in the material handling system for flour and minor ingredients in a bread includes:

Example of a material handling system for flour and minor ingredients (bread line)

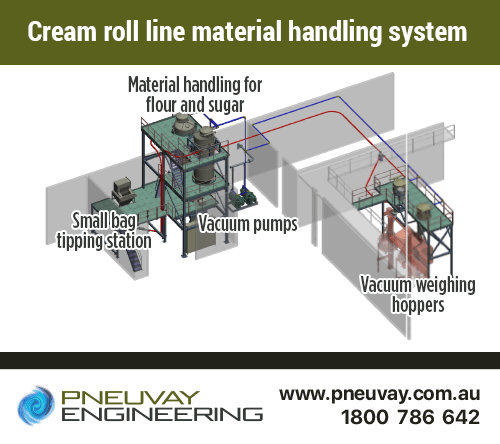

The initial scope of the project was the installation of a simple bag tipping system; however, the recipes required small quantities of ingredients such as flour and sugar to be accurately metered to meet production requirements. This stringent requirement of metering ingredients to a high accuracy represented a major challenge.

Volumetric feeders release a steady quantity of material over time, which provides an economical way to meter materials that have a consistent bulk density. In order to meet this high accuracy dosing, a system using high precision volumetric feeder meters was designed. This system allows ingredient doses, measured in grams, to be metered to a centralized weighing hopper. The pre-weighed ingredients are then transferred remotely to two weighing hoppers, using negative pneumatic conveying (vacuum).

At these hoppers the total pre-weighed ingredients are checked by the Scada recipe management system to verify the amount is within tolerance. If the pre-weighed ingredients are outside the tolerance range, the batch would be discarded and production will not be disrupted.

The high precision, high accuracy and minimum tolerance dosing process demanded a high level of expertise in precision engineering. The sophisticated project was managed in a professional manner and successfully completed.

The systems and components used in the cream roll line material handling system are as follows:

Example of a material handling system for cream roll line

Our engineering group has much experience in the integration of material handling systems in large bakeries. We cover the Asia-Pacific and Middle East regions and are expanding our coverage into Australia. We provide best fit solutions for upgrading large bakeries to expand or improve production. If you have any questions on granular and powder handling systems for a specific food processing plant, feel free to call on 1300721458 or contact us.

More information on granular and powder materials.

Get social with us and see the latest news items from:

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541