See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Friday, May 28, 2021

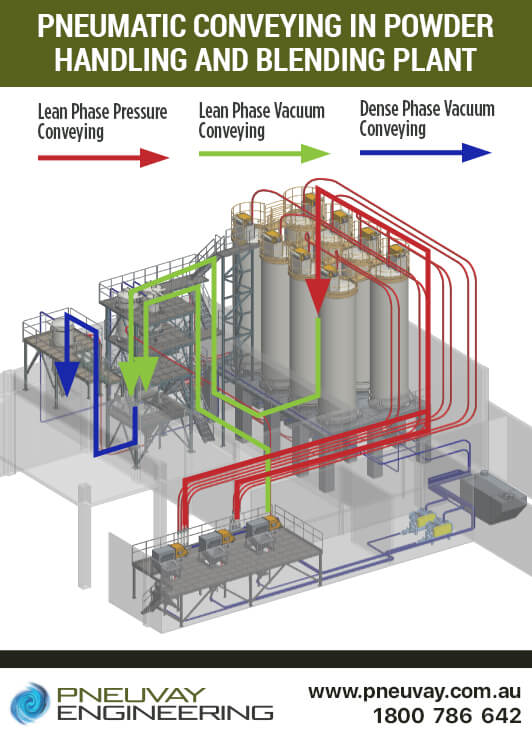

In this section of our case study, we examine the pneumatic conveying, equipment and components within this large-scale powder handling and blending plant. We give a breakdown of where the lean phase pressure conveying (LPPC), dense phase vacuum conveying (DPPC) and lean phase vacuum pneumatic conveying (LPVC) are used to transfer materials throughout the plant. We then detail the equipment and components that were supplied and installed by our engineering group (Pneu Powder Systems) as part of this project.

Our case study on this chocolate milk plant in the Philippines has the following sections:

This particular plant uses several types of pneumatic conveying to transfer the powder ingredients within and between the various stages.

Lean phase pressure conveying (LPPC) is used to transfer raw materials from the tipping stations to silos. It uses cool dry air generated by the dehumidifier and is pressured by a booster fan and two pressure blowers.

Lean phase vacuum conveying (LPVC) transfers raw materials used from silos to the weighing hoppers. It is also used to transport minor ingredients from the tipping stations to the weighing hoppers. Vacuum pumps in the weighing hopper structure are used to generate the vacuum.

Dense phase pressure conveying (DPVC) transfers the final product from the buffer hopper to the receiving hopper above the packing machines. Vacuum pumps near the receiving hopper are used to generate the vacuum. Cool dry air from the dehumidifier and booster fan are used to prevent condensation in the pipeline.

The conveying pipework utilised throughout the plant is three-inch 316 stainless steel and uses typical components such as a diverter gate, Y-branch and butterfly valves. Equipment that provides specific functions, such as dehumidification, magnetic separation and dust collection, is integrated on and between several of these stages. More on flow and stages of material handling within powder food processing plants.

Pneumatic conveying in the chocolate milk powder handling and blending plant

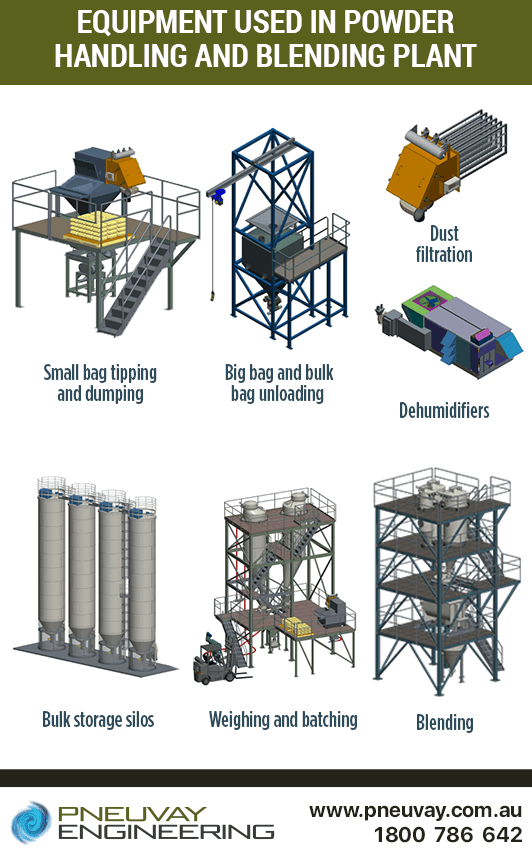

Numerous pieces of equipment were required throughout the processing plant for the powder handling, blending and pneumatic conveying of materials. These were supplied and integrated. The table below details how each piece of equipment is used, positioned and integrated into the plant.

| Equipment | Use and position in the plant |

|---|---|

| Big bag and bulk bag unloading | The bag tipping stations have access to a one-tonne electric hoist to unload big or bulk bags into each of the stations. More on how this equipment is integrated into the unloading stage of the plant. |

| Small bag tipping and dumping | Small bag tipping and dumping equipment used for the bag tipping stations. Each station has its own sub-control system that integrates with plant SCADA. More on how the bag tipping stations are integrated into other equipment in the unloading stage. |

| Bulk storage silos | Stainless steel silos, 20-tonne capacity each, are used for storage of several types of dry bulk materials. More on how these silos are central to the operation of the plant in the storage stage. |

| Blending | Paddle mixer under the weighing hoppers is used to blend raw materials and minor ingredients into the final product. More on how the paddle mixer is integrated to receive and dispense materials as part of the blending stage. |

| Weighing and batching | Weighing hoppers weigh material for the paddle mixer, and receiving hoppers batch final product for the packing machines. More on how the weighing hoppers in the processing stage and receiving hoppers in the packing stage are integrated in their respective stages. |

| Dehumidifiers | Dehumidifier unit to make and supply cool dry air for pneumatic conveying throughout the plant. More on how the dehumidifier integrates within the plant. |

| Dust filtration | Dust filtration is provided by several dust collection systems in and around the plant. More on how dust filtration is integrated in the bag tipping stations, storage silos and weighing hoppers. |

Table of equipment used in the chocolate milk powder handling and blending plant

Equipment used in the chocolate milk powder handling and blending plant

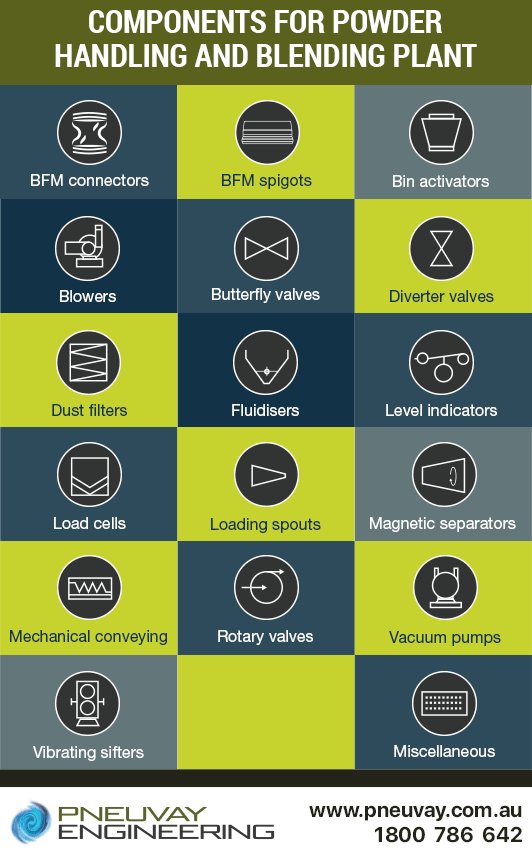

A large range of components was required throughout the food processing plant. Our engineering team (Pneu Powders Systems) supplied and integrated these components into the equipment used in the pneumatic conveying, powder handling and blending systems. Our expertise and industrial experience in component selection and installation is an important part of our total system approach.

| Component | Use and position in the plant |

|---|---|

| Aspiration units | Used for dust control in and around the bag tipping stations, storage silos and weighing hoppers areas. |

| Bag lifters | Used to lift big or bulk bags to the bag tipping stations. |

| BFM connectors and spigots | Used throughout the plant and attached to equipment such as bag tipping stations, vibratory sifters, storage silos, weighing hoppers, discharge chute, paddle mixer, buffer hopper, receiving hoppers, intermediate hopper and trouser hopper. |

| Bin activators | Used beneath silos to dispense raw materials from the storage area. |

| Blowers | Used to generate positive pressure air to convey materials from bag tipping stations to silos in the blower room. |

| Booster fan | Used to generate cool dry air for conveying materials from buffer to receiving hoppers and increase output of cool dry air coming from pressure blowers. |

| Butterfly valves | Widely used throughout the plant, along the pneumatic conveying pipe network. |

| Diverter valves | Used in pipe work that connects the buffer hopper to direct the final product to either of the two receiving hoppers. |

| Dust filters | Snaptex filters are used in aspirators for the bag tipping stations, silos and weighing hoppers areas. |

| Electric hoist | Used for lifting and lowering big and bulk bags in the bag tipping station area. |

| Fluidisers | Attached to many pieces of equipment including the weighing, buffer, receiving, intermediate and trouser hoppers, as well as the vibratory sifters. |

| Hoppers | Several types are used in the plant, including the weighing, buffering, receiving, intermediate and some requiring custom design. |

| Inspection hatches | Used on the weighing hoppers, discharge chute, buffer, receiving, intermediate and trouser hoppers. |

| Level indicators | Used on equipment such as the bin activators and silos as well as the weighing, buffer, receiving, intermediate and trouser hoppers. |

| Load cells | Used in the storage silos and weighing hoppers. |

| Loading spouts | Used in the vibratory sifters, bin activators, discharge chute and paddle mixer. |

| Magnetic separators | Used to filter product on the pipelines from bag tipping area to the storage silo. |

| Mechanical conveying | Used to load small bags of material into the bag tipping stations. |

| Packaging waste removal | Used to dispose of small bag packaging in the bag tipping stations. |

| Pipework | Used to connect the dehumidifier to vibratory sifters beneath tipping stations to silos, bin activators under silos to weighing hoppers and buffer hopper to receiving hoppers. |

| Rotary valves | Used beneath the vibratory sifters in the bag tipping stations area and beneath the bin activators in the storage silo area. |

| Screw conveyors | Used under the trouser hopper to transfer final product to the packing machines. |

| Toyo spring hoses | Used to connect pipework to silos and weighing hoppers. |

| Vacuum pumps | Used to generate vacuum to convey product from silos to weighing hoppers. |

| Vibrating sifters | Used under the bag tipping stations to remove oversized particles from materials being fed into the plant. |

Table of components used in powder handling and blending plant

Components used in powder handling and blending plant

This example of this powder handling and blending plant project is detailed and broken into several major sections including:

We also has a list of other food processing plants case studies completed by the engineering group.

Pneuvay, through its integration with the Pneu Powders Systems group, is a market leader when it comes to pneumatic conveying for food powder processing plants. We cover Australia and New Zealand, as well as from Asia-Pacific through to the Middle East. Contact us are looking for assistance with the design and installation of pneumatic conveying systems for a food powder processing plant. Our engineers are happy to help and provide the assistance you need. Call on 1300721458, contact us with our online form or message us on our Facebook page.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541