See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, October 25, 2023

Venturi eductors are an effective way to move powders, pellets and granular bulk solids in a process known as lean phase (dilute) pneumatic conveying. They are widely used in cement, food processing, mining, power generation and other major industries. Venturi eductors are also known as ejectors, injectors, jet pumps and venturi pumps.

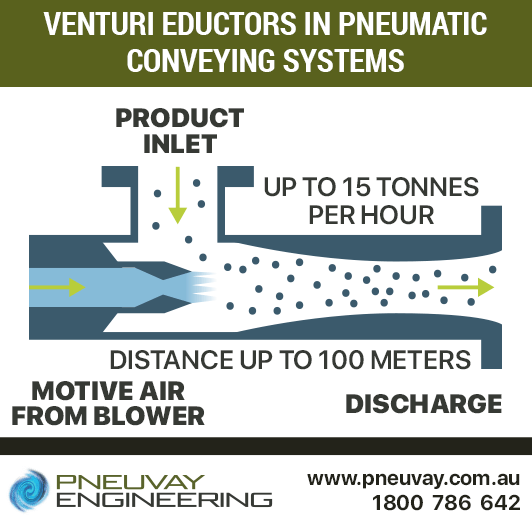

A venturi eductor is the section of a pneumatic conveying system that transports a given product (powders, pellets and granular bulk solids) over a fixed distance and height. These devices use the venturi principle to entrain low pressure air with a high pressure air stream. The mixture converts to an intermediate pressure as it discharges through the length of the eductor. Venturi eductors can pneumatically convey up to 15 tons of product per hour over distances up to 100 metres . As they have no moving parts they generally operate maintenance-free for many years.

A venturi eductor converts the pressure energy of a high pressure air stream (the motive) into velocity. The motive expands through the eductor nozzle to create a vacuum. This entrains the low pressure air that contains the product and creates suction. The two air masses and product are mixed and become re-pressurised within the eductor to an intermediate pressure. As the re-pressurisation occurs and the velocity is converted back into pressure, the product is transported through the eductor to finally discharge from the outlet nozzle.

Venturi eductors in pneumatic conveying systems

Venturi eductors require only a positive pressure from a suitable blower to drive the conveying process. They are an effective alternative to using rotary valves or electric pumps as the mechanism to drive the product transport.

Venturi eductors are superior to rotary valve-based conveying systems when the product is abrasive, fine, fragile or irregularly-shaped. These devices can safely operate in hazardous or high temperature environments where electrical pumps cannot.

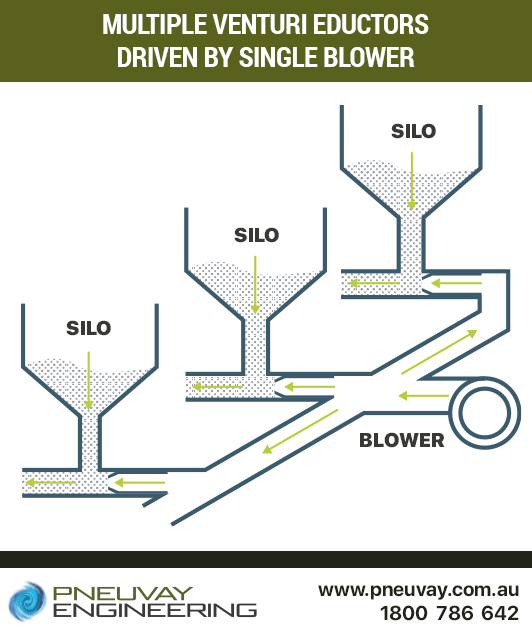

The output level of a blower connected to the venturi eductor is the dominant factor used when designing a pneumatic conveying system. The blower output can be easily adjusted to meet the transport requirements of a given product over a given length. One blower with a sufficiently high level of output can be used to drive a pneumatic system that has many eductors. Further, pneumatic systems can be configured so a venturi eductor outputs via multiple outlets (typical in large dust collectors).

Venturi eductors can also be combined with regenerative blowers mounted on a mobile cart to make a portable pneumatic conveying system. Regenerative blowers have an impeller that spins within its housing, which has both an inboard and outboard channel. For more information on regenerative blowers you can read centrifugal blowers vs regenerative blowers.

Venturi eductors can also be combined with regenerative blowers mounted on a mobile cart to make a portable pneumatic conveying system. Regenerative blowers have an impeller that spins within its housing, which has both an inboard and outboard channel. For more information on regenerative blowers, you can read centrifugal blowers vs regenerative blowers.

Multiple venturi eductors driven by single blower

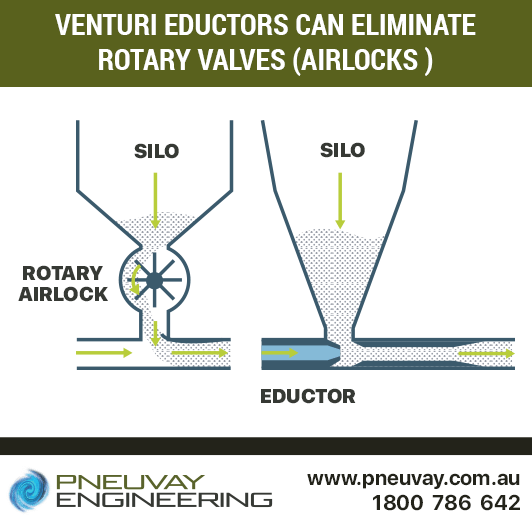

The replacement of rotary valve-based systems with venturi eductors may be feasible in certain situations. Venturi eductors make for simpler, more reliable conveying systems that can better transport sensitive or irregular products. They can also provide significant improvements, such as:

It is ideal to engage experienced design experts when implementing installation of a new pneumatic conveying system. They can determine from the start whether the system can work with venturi eductors. This will avoid having to replace, at a later date a, system that was first designed with rotary valves.

When considering retrofit and replacement of an existing rotary valve-based system with a venturi eductor-based one, it is recommended that experienced design experts be engaged. Retrofitting existing pneumatic conveying systems with eductors can have some technical and commercial challenges. Detailed analysis of the existing blower, pipe geometry, dust collection and conveyed rate material is required to check feasibility.

All rotary valves have some level of blowback (fugitive dust or leakage). The blowback from abrasive or fine product can cause extreme wear to rotary valves. They suffer from bridging and housekeeping problems and can pose explosion risks. Slide gates can be used to reduce blowback in rotary valves but this is not always possible.

As venturi eductors have no moving parts they do not cause the product damage typical when using rotary valves. Movement through a rotary valve of abrasive, fine, fragile or irregularly-shaped products can result in mechanical shearing, smearing or degradation.

Venturi eductors can eliminate rotary valves in pneumatic conveying systems

Below is a list of some of the bulk powder, pellets and granular products conveyed with venturi eductor based systems.

For more than 30 years Pneuvay has been providing help to the Australian industry on venturi eductor-based pneumatic conveying systems. We have experience working with a broad range of Australian companies, designing, installing and maintaining venturi eductor systems that:

If you have any questions in relation to venturi eductors, feel free to call us on 1300721458 or send us a message via our Pneuvay website contact page or Pneuvay Facebook page.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541