See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Monday, April 30, 2018

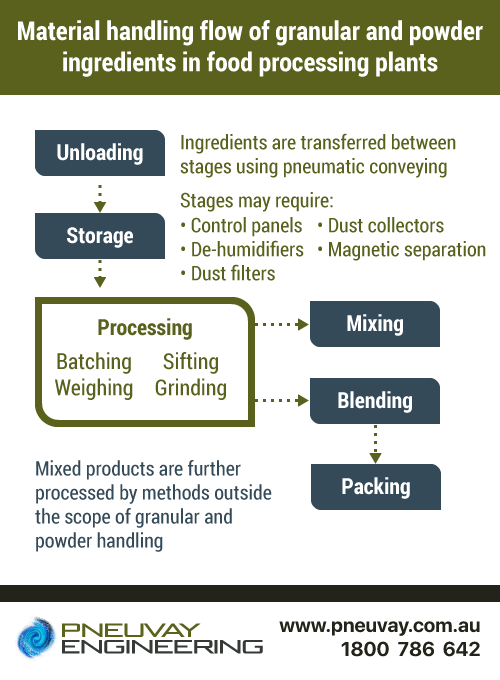

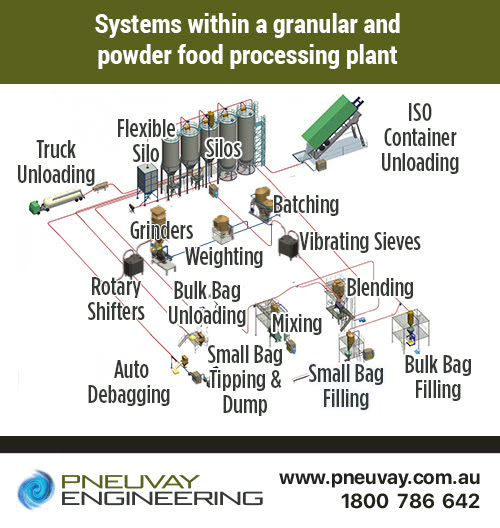

A modular structure for material handling flow is used to understand how granular and powder food processing plants work, what they do and how best they should be developed. This breaks the material handling flow into distinct connected stages that follow a typical order. Transfer of granular and powder ingredients within or between stages is done by pneumatic conveying.

These distinct stages and the order in which they connect are:

Each stage will typically have custom control panels and dust collection systems. Some stages may require dehumidifiers and magnetic separator systems.

Material handling flow of granular and powder

ingredients in the food processing industry

Unloading of granular and powder ingredients into a food processing plant can occur via several methods. Truck or ISO container unloading systems are used to transfer bulk volumes of material (up to 30 tonnes) into a storage area within the food processing plant. They generally require specific discharge aids such as fluidisers and aerators.

Smaller volumes of material can be brought into the plant using bulk bags (500kg to 1,500kg) or small bags (up to 25kg). The material can be sent to a storage facility; however, it is generally fed directly into the processing stage.

Bulk bag unloading systems have electric hoists that allow operators to lift and position the bags above vibratory dischargers. Small bags (25kg) can be unloaded using various types and configurations of tipping and dump systems. These are usually manual systems that deal with much smaller volumes compared to the other unloading systems. Auto debagging systems can be coupled with tipping and dump systems to improve efficiency. They cut away and remove ingredient container bags so the contents can feed automatically into the processing plant.

Systems used in unloading stage include:

Accessories used in systems within the unloading stage include:

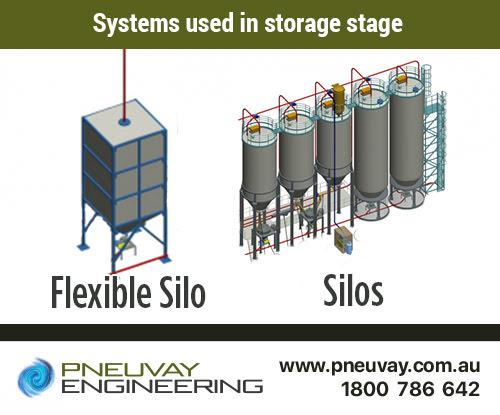

Systems used in unload stage

There are two main storage methods for holding granular and powder ingredients within a food processing plant. Silos are used for holding large volumes (up to 75 tonnes) of dry bulk ingredients such as dairy powders, flour, sugar, starch and salt. They are generally made from mild steel, stainless steel or aluminium and deployed outside the plant; however small silos can be deployed within a plant to provide temporary storage for buffering. They can be supported using skirting or a leg structure. Most silos need to be specifically designed to meet the requirements of the food processing plant, and their design is dependent on the type and characteristics of the ingredient to be stored.

Fabric flexible silos are a special type of storage system. These are always deployed within the plant and are made from durable, tough, dust-proof and non-toxic fabric. They are made in standard sizes however they can be customised to specific dimensions. Fabric flexible silos are light and come with a galvanized steel frame that can be readily assembled. The ingredient is pneumatically loaded to the top of the fabric flexible silo and then descends by gravity. The silo fabric walls allow for a smooth discharge of the ingredient from the bottom where extraction is made either by a screw conveyor or rotary valve. The fabric is air permeable to avoid agglomeration of the ingredients via condensation.

Systems used in the storage stage include:

Accessories used in systems within the storage stage include:

System used in storage stage

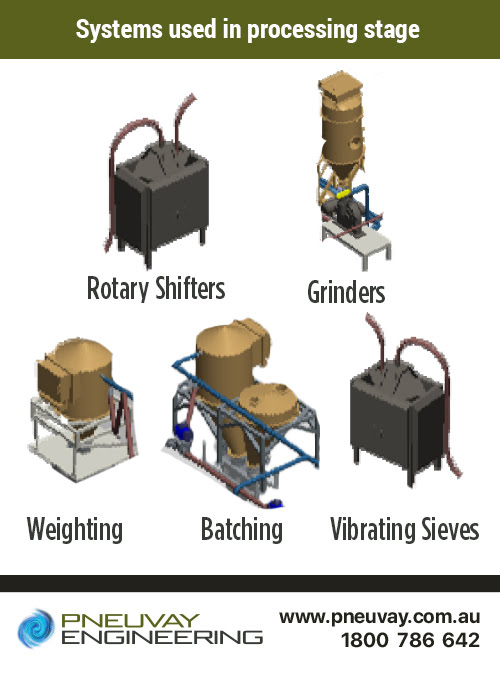

Processing of granular or powder ingredients involves applying one or more operations prior to mixing, blending or packing. Processing operations include the use of grinding systems to reduce raw ingredient particle size, or vibrating sieves and rotary sifters to remove ingredient impurities or irregularities. Processing also involves such operations as the weighing and batching of ingredients to accurately meter ingredient volumes, which are then fed into subsequent processes or stages.

Systems used in the processing stage include:

Accessories used in systems within the processing stage include:

Systems used in processing stage

In a granular and powder food processing plant, mixing is often associated with combining solid ingredients with large quantities of liquid ingredients. Mixing involves combining the ingredients in a vigorous fashion to form a homogenous product. The mixture then either remains a liquid or becomes a semi-solid, such as a dough, paste or cream. Mixed products are further processed by methods outside the scope of granular and powder handling. More information on mixing.

Accessories used in systems within the mixing stage include:

Accessories used in mixing stage

The blending of granular and powder ingredients involves combining them in a gentle fashion so that they become inseparable but not necessarily homogeneous. Blending is associated with the combining of solids with solids, or solids with small amounts of liquids. Examples of blends are powdered milk products, cake mixes, and colouring being added to expanded cereals. Blended ingredients are typically transferred to the packing stage. More information on blending.

Components used in the blending stage include:

Accessories used in blending stage

Packing includes the weighing and filling of the product into bags. There are two methods used for the packing of processed or blended products from a granular or powder food processing plant. Bulk bags filling systems handle quantities from 500 to 1500 kg while small bag filling systems process quantities up to 25 kg. Both types of systems can be fully or semi-automated.

Systems that are used in packing stage include:

Accessories that are used in systems within the packing stage include:

Systems used in packing stage

Granular and powder ingredients are transferred within and between stages using pneumatic conveying. This type of conveying generally occurs within and between the unloading and processing stages.

There are four types of pneumatic conveying used, and which method is utilised depends on many factors. The methods used are lean phase pressure (DPPC), lean phase vacuum (LPVC), dense phase pressure (DPP) and dense phase vacuum (DPVC). Note that other terms are used including:

Components that are used in pneumatic conveying systems include:

Pneuvay is a leading system integrator for material handling of granular and powder ingredients in the food processing industry. We cover Australia, the Asia-Pacific and the Middle East. We provide optimal solutions for the various stages, systems and accessories required in food processing plant development. If you have any questions on material handling flow for a specific granular and powder food processing plant, feel free to call on 1300721458 or contact us.

Systems within a granular and powder food processing plant

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541