Our pneumatic conveying products for the food processing industry provide

maximum performance while minimising operating costs.

Are you looking for more efficient pneumatic conveying equipment that delivers:

We have been designing and fabricating durable and reliable pneumatic conveyors in the food processing industry for several decades. Call us at 1800 786 642, today or click here to Contact Us.

There are different types of conveyors you can use in the food processing industry. But why choose pneumatic conveying equipment over mechanical? Here are the reasons:

Our team of pneumatic conveying experts is happy to design a cost effective solution for your industry needs. Complete our online form and we will respond to you within the business day.

We have been designing and fabricating pneumatic conveying products for the food industry for the more than three decades. This is what one of our clients many have to say about us:

"I am very impressed with the crew's technical expertise across a wide variety of automation platforms and their ability to always produce a great result in a timely manner."

Andrew Keil

Site Manager of Laucke Flour Mills Pty Ltd

Click here to see what our clients have to say about us.

We give you the opportunity to experience the same advantages with these products:

Read about our case study

This is a low cost alternative to installing a complete vacuum system. It is used for general cleaning, medium to heavy pick-up of materials including hazardous liquids and explosives.

Industrial Air Vacuum Systems for the Food Processing Industry

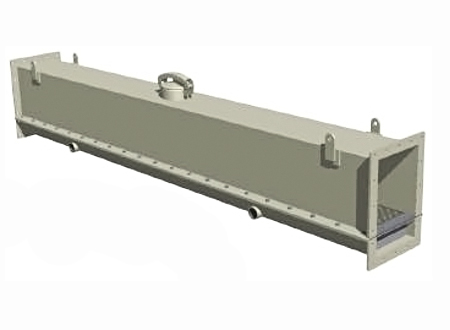

Our air slide gravity conveyors have the capacity to transport bulk powders from silos into the pneumatic conveying system for the food processing industry. These are specifically designed for aeration of dry bulk materials resulting to a smooth and even flow throughout the entire conveying length.

Pneumatic conveying air slide system for the food processing industry

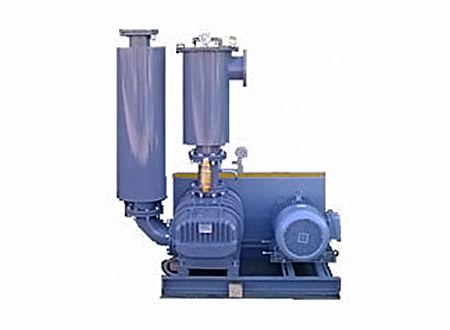

Our pneumatic conveying blowers and air fans are most helpful in circulating air in ovens and dryers to eliminate cold spots. However, it is also used for general ventilation of rooms or factories, drying ink on cans and bottle, silk screen and printing processes, pressurizing cabinets and vaults, conveying material in dust collector systems, combustion air for burners and industrial water heaters and blow-off systems for the removal of moisture from parts prior to painting, packing or coating.

Pneumatic conveying blowers and air fans for the food processing industry

We design and custom build dust collector and extractor systems that meet your specific requirements. This includes fabrication of dust capture arms, bin vent dust collectors, portable dust collectors, industrial ductwork, personnel environmental booths, cartridge filter dust collectors and air showers.

Dust Collectors and Extractor Systems for the Food Processing Industry

We ensure your workstation is free from dust contamination including particles visible only through an electron microscope. We keep installation and operation costs at a minimum while protecting your workforce from solid pollutants. Learn how our air cartridges and filters can help you in your application. Talk to us at 1800 786 642.

Dust free work station using dust filters and dust cartridges

We have high quality equipment and devices suitable for conveying continuous edge trim and paper off cuts to make your daily operations more efficient. See how its flexible and eco-friendly design can increase your productivity.

See video of pneumatic conveying multi cutter and trimmer in action

Pneumatic conveying multi cutter and trimmer for the food processing industry

We fabricate pressure pots to meet your specific food processing industry requirement. These devices are sturdy, resistant to corrosion, portable and made from high quality metal. Tell us your requirements and we will design a cost effective equipment suitable to your needs.

Pressure pots for material transferring applications

Bulk materials have various demanding requirements in the areas of:

It is a daunting task to some, but here at Pneuvay Engineering it is an element we have proudly mastered. Our years of experienced in the design and fabrication of dense phase pneumatic conveying products allow us to custom-build equipment according to specific products and applications.

Movement of goods with the aid of air to entrain, suspend and transport particles along a pipeline, referred to as pneumatic conveying, has long been used by industries.It is performed by injecting compressed air into one end of a pipeline or along the pipeline and has been categorised into:

Basic principle: low-pressure, high velocity system

Lean phase pneumatic conveying systems utilized either negative or positive pressure to push or pull materials through the convey line under high velocities.

Commonly Conveyed Products Using Lean

Phase Pneumatic Conveying

Basic principle: high pressure, low-velocity system

The working principle behind dense phase pneumatic conveying systems is simplicity, reliability and flexibility. It is designed to deliver utmost productivity by transferring materials from a single collection point to either a single or multiple reception points. Most importantly, it allows industries to transfer almost all types of bulk solid materials while ensuring low level of particle damage.

Commonly Conveyed Products Using Dense

Phase Pneumatic Conveying

Industries often have their materials tested prior to final system selection. Our years of experience allows us to provide accurate advice on how to best handle your requirement based on material use. Talk to our engineering experts at 1800 786 642 for reliable engineering consulting services.

Featured Product: Venturi Blowers

Other materials:

Working Systems:

Product Applications:

Click here to learn more about our Dimattina and

Coffico Coffee Houses Project.

Interested to have your own dense phase or lean phase pneumatic conveying systems be designed and fabricated by our team of experts? Complete our online form and we will respond to your within the business day.

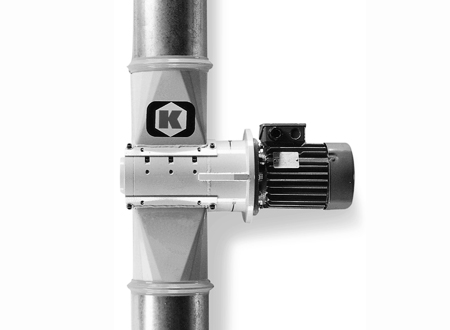

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags