All ducting and extraction technology supplied by Pneuvay Engineering

for this project was installed according to Australian Standards.

The "Unit Parts" plant of Toyota in Australia is the manufacturing warehouse for the components of the new lines of Camry and Aurion. Thus, it requires a large scale welding fume extraction to be implemented in its new Australian plant.

This project is the largest integrated installation of Donaldson Downflo collector technology in Australia. It impressively features:

With these components, the system is designed to effectively handle:

All ducting and extraction technology supplied by Pneuvay Engineering for this project was installed according to Australian Standards as

well as Toyota's stringent global benchmark on OH&S and environmental management.

Integral to the integrated technology of this system is Donaldson's DF04-80(x4) series fume extraction system that uses FR Ultra Web filters. Toyota laid down a strict project brief with a requirement for completely contained extraction of fumes generated by robotic welding and the integration of the fume extraction system was paramount in the new building to meet Toyota's strict OH&S requirements.

With the plant's capacity to operate on a 24/7 basis, it was imperative to ensure that the system to be engineered completely contains the mist from the moment it is sucked through a collection point to the time it emerges as clean air.

The entire installation is situated outside the plant with more than 25 metres of length. Our team has to install duct systems throughout the new building, reaching nearly 300 m of ducting, to guarantee it will draw the fume generated by the robotic welding activity effectively. With this, the fume is drawn up into any of the four (4) spark arrestors through the 1200mm in diameter of duct lines. From there the fume is transferred into a primary manifold and is passed through the filtration process filters. Clean air is then discharged, ready be released into the atmosphere or directed back into the building (which has conditioned air) free from environmental hazards.

Large Dust Filtration System Installed at Toyota Altona Victoria

Large Dust Filtration System Installed at Toyota Altona Victoria

Main Fan at Toyota Altona Project 200KW

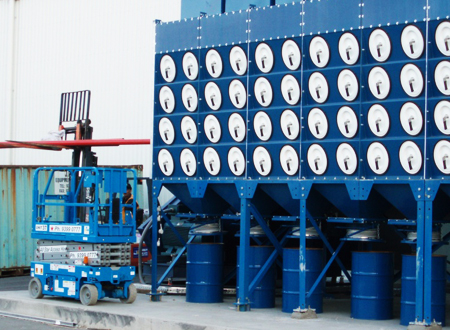

Downflo Installation in Australia with over 280 cartridges

The largest Downflo Installation in Australia with over 280 cartridges

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags