See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Friday, May 20, 2016

Food processing equipment systems design involves many factors. This includes the following principles, as discussed in our blog, "Designing food processing equipment: More than meets the eye."The operation of a system must not contribute to unhygienic conditions that can lead to microbial increase in the equipment throughout the course of a day.

As an example, a problem occurs when a processor operates a wet process that moisturises the conveyor belt all the time, making risks high for bacteria growth.

"In an ideal world, the processor wants to increase productivity and run the lines as efficiently and safely within the regulated timeframe," said Joe Stout of Food Safety Magazine.

It is a must then that system designers see to it that an equipment's conveyor and its other parts minimise moisturisation and product buildup.

The American Meat Institute (AMI) also advises that maintenance enclosures be not only cleanable, but engineered in a way that doesn't leave any room for product or liquid storage. This includes items such as:

"The same goes for human machine interfaces like valve handles, switches and push buttons. Their physical design must be sloped or pitched to avoid being a storage area," Joe told.

Though the EDTF acknowledges that there are exceptions to the rule, it doesn't fail to stress the importance of maintenance enclosures and other connecting parts to an equipment be sanitisable for better food safety measures.

Another vital sanitation design measure to consider is an equipment's compatibility with other existing systems in a plant.

Joe noted that it is a shared responsibility between the equipment manufacturer and the food processor. Hence, processors need to educate first the machine manufacturers of the current systems in place in their factory.

Processors should inform manufacturers of "established electrical, hydraulic, steam, compressed air and oil filtration and water systems" prior to the construction of their required machine.

This task lies more on the side of the food processors as system manufacturers are not cleaning procedure experts says Joe.

Food processors on the other hand deal with system sanitising day by day, and can thus give useful insight on the best way to clean the equipment. Processors must clearly define hygienic procedures that have been proven effective and efficient. This includes the chemicals which are deemed compatible with the equipment and the manufacturing environment.

The AMI recommends that during the design stage, the equipment manufacturer work closely with the food processor and talk about how the machine should be cleaned. Doing so will help foster education between the two groups when it comes to successfully completing hygienic equipment design: The processor can better understand how a machine operates and in turn provide vital sanitizing information to the manufacturer.

"While we take every engineering challenge seriously, we believe that designing systems for the food industry weighs a bit more," said Michael Francis, Managing Director of Pneuvay Engineering.Pneuvay has provided pneumatic conveying solutions to some of Australia's trusted names in the food industry like Wimpak and Glencore.

"One of the primary things that we had to consider with our project with Wimpak and Glencore was adhering to safety standards set by the government and the company's as well. We know that we were able to achieve that through our established communication with our clients," stated Pneuvay's Engineering Manager Paul Malcolm.

As the EHEDG and AMI have emphasised, the education of and cooperation between equipment manufacturers and food processors pre-equipment fabrication are vital for a number of good reasons. One apparent would be that their joint efforts can yield a machine to last for decades that is easily cleanable and sanitisable.

More vital however, their constant communication and knowledge exchange can contribute to the future of safety standards in the food industry in general. Be it in an exchange of ideas or simply giving feedback to organisations that create and safeguard food hygiene tenets, the information they can provide may even become part of the literature on hygienic equipment and processing widely available but, as Huub said, not always applied.

Like good food, there must be more to designing hygienic food equipment than meets the eye — and primarily because the health and safety of consumers relies on it.

Comprised of equipment manufacturers, food industries, research institutes as well as public health authorities, with one common goal, the European Hygienic Engineering Design Group has been promoting hygiene in food processing and packaging since 1989."

Chartered by the Listeria Task Force of the American Meat Institute, the Equipment Design Task Force is tasked with formulating "equipment sanitary design principles that meet the expectations of the meat and poultry industries."

Apart from establishing sanitary design principles, the AMI EDTF has also recommended a certification process to ensure that food processing system adheres to the said principles.

Get social with us and see the latest news items from:

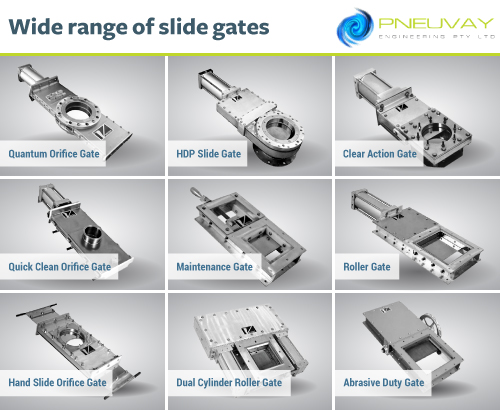

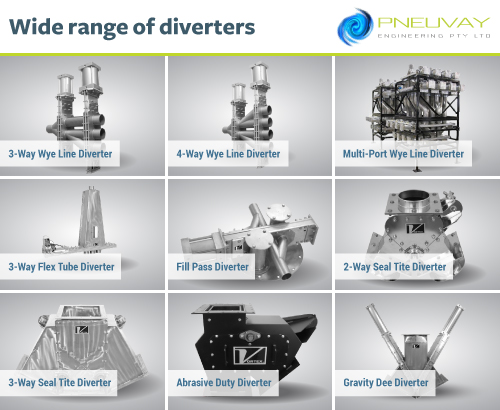

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541