Is there a dust extraction system for woodwork that can address this concern?

.

What are safe dust levels for woodwork?

The Environmental Protection Agency (EPA) released assessment guides to ensure that wood dust released on workshops would not cause harm to the environment. This includes the following:

- Sawmills and wood production

- Joiners and cabinet makers

- Carpenters working indoors

- Schools with wood working workshops

One of the requirements greatly emphasised in the publication is the maintenance of good air quality in and out of a woodworking area especially to residential premises.

Recommended minimum separation distances between types of wood processing works and sensitive receptors (e.g. residential premises) are presented in the following table.

Industry standards for dust extraction systems for woodwork

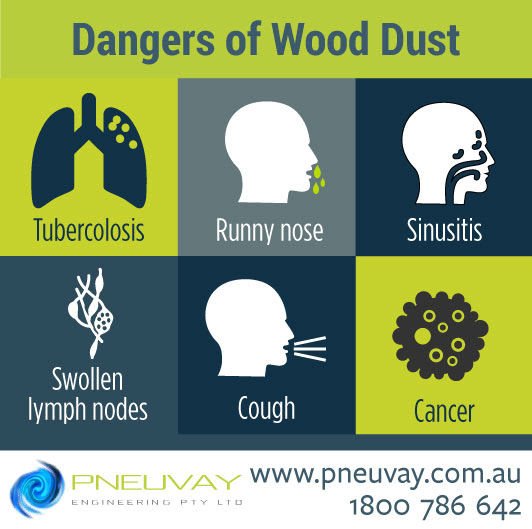

Dangers of inhaling too much wood dust

"Woodworkers face 70 to 80 times the risk of a particular form of nasal cancer." doctors say.

"It says about 50 people a year are diagnosed with nasal cancer which may have developed decades after their exposure to wood dust, while others have asthma as a result of their occupation."

Wood dust is also ranked at 38 in the 116 things that can give you cancer says International Agency for Research on Cancer.For the full list of cancer causing things, refer

here.

Aside from cancer, inhaling too much wood dust may also cause allergic respiratory systems, mucosal and non-allergic respiratory symptoms. That's how dangerous and deadly over-exposure to wood dust is.

Without proper way to prevent dust, woodworkers are highly at risk of nasal cancer

.

Sources of carcinogenic wood dust in industries and workshop

In general, wood dust or sawdust is a byproduct of wood processes, including

Based on recent studies, there are certain species of hardwood that produces carcinogens. This includes:

- Oak

- Mahogany

- Beech

- Walnut

- Birch

- Elm

- Ash

- MDF

What are the dangers of MDF especially to joiners, cabinetmakers and carpenters?

The dangers of MDF happen during the machining and sanding process. Since it contains a mixture of softwood and hardwood dust, as well as free formaldehyde, the dust particles which formaldehyde is adsorbed becomes a major health risk to joiners, cabinetmakers and carpenters.

The Workplace Exposure Limits (WELs) for hardwood dust, softwood dust and formaldehyde are expressed in the number of milligrams (mg) of material in one cubic metre of air (m3) are as follows:

- Formaldehyde - 2.5 mg/m3 or 2 ppm for both the long-term exposure limit and the short-term exposure limit

- Hardwood and softwood dust - 5 mg/m3 for the long-term exposure limit. There is no short-term WEL

The above limits show two exposure terms: long-term (8 hours) and short-term (15 mins). The long-term represents a working day which may result to various respiratory problems such as asthma and nasal cancer. On the other hand, the short-term or 15-minutes exposure may result in eye irritation immediately after exposure to MDF.

How to control the level of exposure to MDF amongst joiners, cabinetmakers and carpenters

To control exposures, employers should follow the 'hierarchy of control' set out in the Control of Substances Hazardous to Health Regulations (COSHH) Regulations. This means:

- Reducing risks at source by using a lower risk alternative, where one exists.

- Installation of an effective dust extraction system

- Use of mobile vacuum cleaners with high performance filters (HEPA) to clean up MDF dust, or use a hose connected to the LEV system.

- Use of Respiratory protective equipment (RPE) as last line of protection

Ensure the safety of your workers. Talk to us so we can design a customised dust collection system for your business.

What to consider when looking for dust extraction systems for woodwork?

This may sound simple, but you have to carefully evaluate the following parts of your dust collection system:

- Fittings and attachments

- Flex hose and ducting

- Dust filters and bags

- Shop vacuums and air cleaners

- Dust collectors and cyclones

All of these parts should be properly designed and installed to ensure you your workshop is free from dangerous "dust pumps".

Selecting an appropriate dust extraction systems for woodwork

In selecting a suitable dust collector, you must address the following:

Types of wood dust

Wood dust are generally categorised into three which are:

- Class I - Light or fine dust commonly from sanding process

- Class II - Medium-sized dust commonly from moulders and saws

- Class III - Larger and more fibrous dust commonly from millers and planters

Types of wood dust

Dust characteristics

There is no dust collector applicable for all dusts and for all workshop processes. Different workshops have different characteristics.

Below are some of the other factors you should consider when categorising wood dust:

- Is the wood hardwood or softwood?

- Is the wood dried or 'green' (very moist)?

- What materials create the dust such as particleboard?

- Are there other particles included in the dust

Best practice in designing and installing dust extraction systems for woodwork

Woodworking makes so much dust that exhaust fans and air cleaners cannot lower the airborne dust levels fast enough to keep it from failing air quality tests. The only way to ensure passing air quality tests is to collect the fine dust as it gets made.

Why? Once fine dust escapes collection normal room air currents rapidly spread this dust to evenly fill any attached space just like a bad odour. Further, fine dust is easily transported on our clothes, hair and skin to contaminate other areas.

This completely makes sense. Collect the fine dust as it gets made and store it in a dust bag or container. In this manner, you'll be preventing fugitive dust from circulating around your workplace.

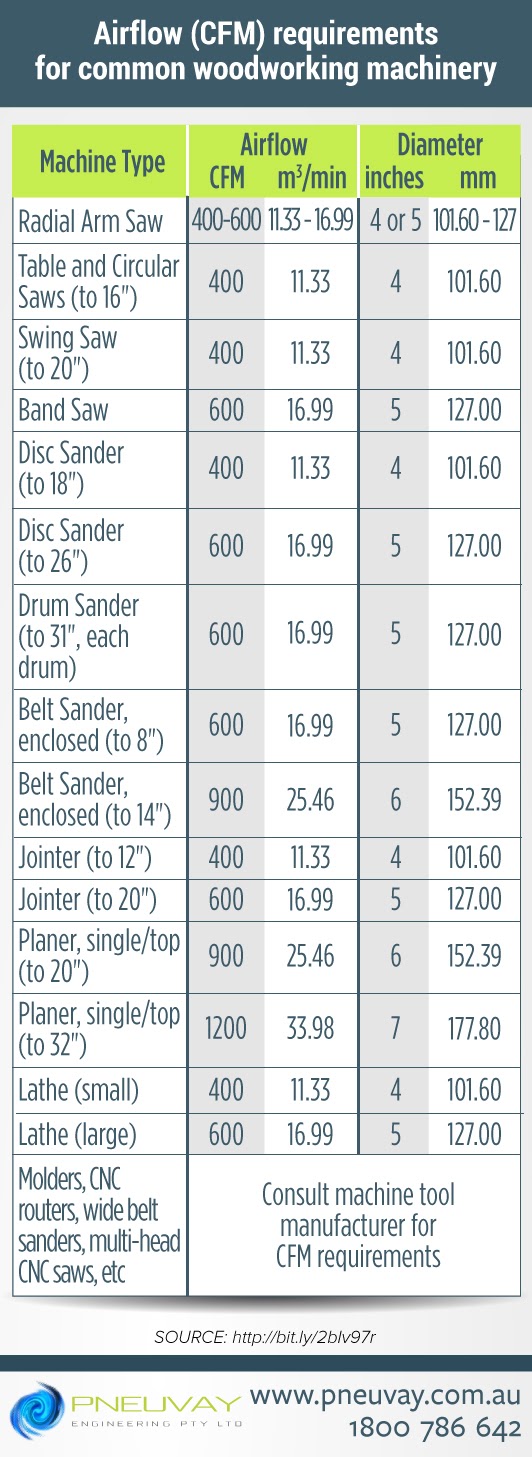

Airflow Requirement

Indicated below is the general airflow requirement for specific machine types that is based on 4,500 ft/min transport velocity.

Airflow requirements for common woodworking machineries

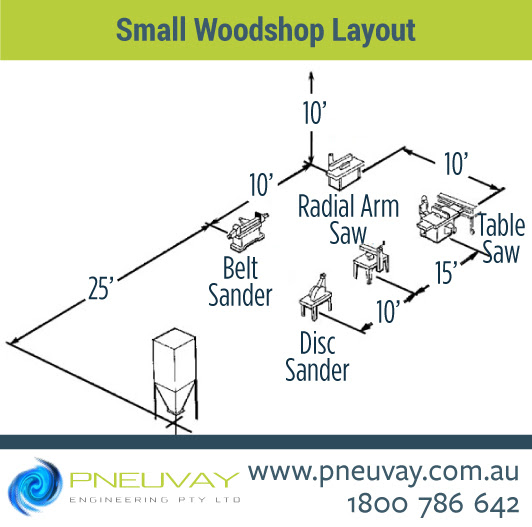

Location of the dust collector

Dust collectors can be placed indoors or outdoors. It can also be mobile or static. The image below illustrates a dust collection system placed indoors.

Dust extractions system for woodworks sample layout

Do you want to know what type of dust collector best fits your workshop or factory? Talk to us at 1300721458.

Volume of dust discharge and disposal

You will need an expert pneumatic conveying engineer to assess the overall volume dust discharge and disposal of your workshop. However, identifying the right dust extraction systems for your needs depends on your answers to the following questions:

Is your production continuous or intermittent?

How many materials will produce dust which will be collected by the dust collector?

We ensure you'll get the most appropriate unit from our range of dust extraction systems for woodwork.

Contact us for dust extraction systems woodwork assistance. Call us at 1300721458.

Dust extraction systems for woodwork and other industries