With various end-use sectors looking for better technology to replace inferior methods, further pneumatic conveying benefits for industries is seen as a motivating factor for its increased growth in the coming years.

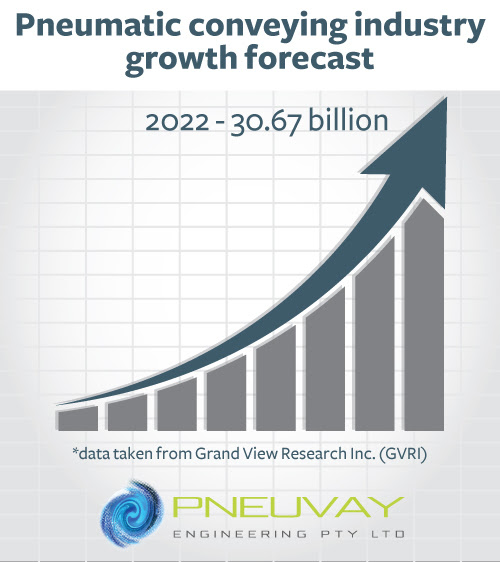

(GVRI) has predicted increased pneumatic conveying growth to US$30B by 2022. This is due to end-sectors, as such listed below, looking for more efficient methods that will better their operation:

The main factors driving the expected growth of pneumatic conveying when transporting powder and granular bulk materials (when compared to other methods) are:

In 2014 alone, the market size of pneumatic conveying system worldwide amounted to USD 20.3 $USD billion according to the company. GVRI added that the industry is expected to be worth $30.67 USD billion by 2022 growing at a rate of approximately 5% each year.

Below are the different pneumatic conveying systems that GVRI sees will attract more business for companies in the said industry in the coming years:

In the forecast, GVRI projects dense phase conveying systems to account for over 70% of the industry's total market share. Pneumatic conveying systems make possible the transport of a thousand kilos of material from one source to another in a matter of minutes. One of the best parts is, it uses air velocity rather than mechanical power which makes it more economical and sanitary for businesses.

Vacuum systems are predicted to have a more than 5% increase in compound annual growth rate (CAGR) within the forecast period. This is attributed to its ability to utilise vacuum created in conveying lines to pull materials towards specific loading points.

Combined vacuum and pressure systems have also been estimated to show moderate growth, especially for industries requiring the transit of materials to and from multiple loading and unloading points.

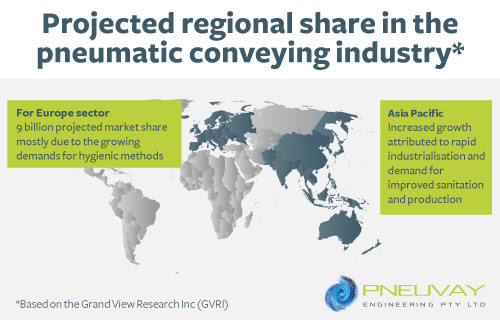

An increased demand for pneumatic conveying systems is expected globally, specifically in these regions:

Europe’s pneumatic conveying companies are projected to take in about $9 billion of the market share in the following years. This is mostly attributed to the growing demand for hygienic methods in the transfer and production of products. Pneumatic transports systems convey materials through an enclosed channel, thus protecting materials from contaminations.

Read more about the rising demand of Pneuvay’s products abroad.

Overcoming challenges in the pneumatic

conveying systems

Pneumatic conveying companies deliver various solutions to boost efficiency rates and save on power consumption. Some even provide 24/7 supports to its clients. However, pneumatic conveying systems do have a high initial capital investment. GVRI sees this as a hurdle that manufacturers must overcome. With this in mind, pneumatic conveying companies are expected to:

- Provide flexible payment options and packages to businesses

- Meet the specialised product needs of their clients

- Implement methods in downsizing capital investments

- Develop simpler installation processes

"Pneuvay Engineering designs and installs pneumatic conveying systems and equipment that suits your specific requirements. We take into account your budget and implement methods to downsize your capital investments. Talk to us to further discuss the various solutions our systems and equipment can do to your business," shared

Michael Francis.

Growth and demand in pneumatic

conveying benefits

Here are additional reasons why companies should be choosing pneumatic conveying systems for their materials transport needs:

Flexible

Upgrading mechanical conveyor systems often require replacement with new equipment and additional workplace. Pneumatic conveying systems can work around an existing workplace. The conveying channels can also be adjusted to seamlessly connect or run through facilities or structures in place. This makes it flexible and more economical in the long term — saving business labour and reducing production time.

Efficient

Another benefit of a pneumatic conveying system is that it is only composed of a few working parts:

- Air compressor

- Vacuum pump

- In-feed device

- Conveying tube

- Separating device

Fewer moving parts means having lesser chances of mechanical failure, thus ensuring reduced downtime. Should a part incur damage at some point, the whole system does not need to be removed from its place. Parts are repairable or replaceable at component level.

Sanitary

The main purpose of pneumatic conveying channels being enclosed is to lock in air and control the flow of air pressure. This reduces spillage during transport to virtually zero, protecting your staff from hazardous materials being conveyed. Sealed-up piping also means that the materials being transferred through it are protected from contamination, which is a must when dealing with food products like wheat, coffee, flour or sugar.

Australian industries taking the

pneumatic conveying advantage

From efficiently and cost-effectively transporting sugar to sand, pneumatic conveying systems are used in a wide variety of industries. Adoption and investment by companies not utilising pneumatic conveying is expected to increase due to the following benefits:

Aviation

With a growing number of airplane designers using carbon reinforced composites, demand for

vacuum equipment systems is taking on new heights as well.

Vacuum systems are used for proper dust extraction and disposal, eliminating environmental risks and operation downtime in major airlines.

Mining

In the mining sector,

dense phase vacuum systems aid in transporting bulk materials from earth minerals to fine sand. Among the common pneumatic solutions in place for this are:

- Large installation vacuum cleaning systems

- Dense phase pneumatic conveying systems

- Mobile vacuum systems

- Laboratory systems

Pneumatic conveying is also used in shotcreting. Shotcrete is a mixture of cement (or mortar) and sand sprayed onto various rock conditions to help reinforce them.

Food processing

GVRI reported that the food industries (including pharmaceuticals) were responsible for over 50% of the market share in pneumatic conveying in 2014, with companies opting for a more sanitary means of product conveyance. Pneumatic conveying can also be applied in various stages of food (including drug) production. In

food processing plants, its functions include the following:

- Drying

- Cooling

- Fermentation

- Dust Extraction

- Fume Extraction

Vacuum systems are especially useful in removing process waste like unfilled confectionery packets or cardboard trim waste. The pneumatic-assisted drying process on the other hand is also vital for other industries like agriculture, ceramics, and polymers and plastics.

Pneuvay Engineering: A testament to

pneumatic conveying benefits

and growth

As a testament to the growing global demand of pneumatic conveying solutions in various industries, here are two of Pneuvay Engineering's major installation projects:

Glencore

Glencore is one of the world’s largest global diversified natural resource companies and a major producer and trader of more than 90 commodities.

In late 2014, Glencore sought Pneuvay’s help in devising and installing a pneumatic conveying system for their new plant in Mount Isa, Queensland. Pneuvay responded and finished the

Glencore Xstrata Project by constructing a 1000-tonne bulk cement handling system with automated silo control, aeration, and dust collection systems. This completely automated system produced a conveying rate of 30 tonnes per hour, reducing the total cycle time it took before the change. The company was able to greatly reduce operational costs, not to mention, increase workers' safety.

Wimpak

Wimpak is Australia’s leading company in cleaning and exporting a wide variety of seeds and grains worldwide. In February 2015, Pneuvay’s

pneumatic conveying installation helped it achieve 100% deliverability of farm products with zero waste. Pneuvay designed a grain handling system that resulted to a flow rate of three (3) tonnes per hour, which ultimately lead to increasing the financial output of local producers' farms.

"Pneuvay is an expert in setting up mobile and fixed plant bulk material conveying systems for grains like corn, soy beans and wheat to load in bulk into silos and trucks," said Managing Director Michael Francis.

WIMPAK General Manager Jo Cameron told that the installation has been timely. "It ensures we can effectively clean grain for our growers while offering competitive prices," he added.

About Grand View Research

Headquartered and registered in San Francisco, California, Grand View Research, Inc. is a U.S.-based market research and consulting company. The

company offers "syndicated research reports, customised research reports, and consulting services," to help their clients form informed decisions about their businesses. They also provide market intelligence studies founded on relevant and fact-based research spanning a variety of industries from technology to healthcare, including pneumatic conveying benefits.