See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Wednesday, February 28, 2018

We will be focusing many of our coming topics on aspects of handling granular and powder materials in food processing plants. This is because we are working hard to become the leading solution provider of granular and powder handling systems for food processing plants in Australia. We will publish detailed articles like this to clearly demonstrate our experience and expertise in this sophisticated industry sector.

Let us begin our overview on this topic with definitions of food processing plants and granular and powder ingredients.

Food processing plants are factories that combine raw and processed ingredients to make food products that can be used in further food processing or are ready for consumption.

Granular ingredients are solids made up of tiny grains or small particles. For example, sugar is a typical granular ingredient. The particles can also be extruded pieces, flakes or pellets. Powders are a type of granular ingredient where the particles are very fine. They are a special case because fine particles behave differently to tiny grains and small particles. An example is flour, which is a common powder ingredient. More information on granular and powder materials.

Examples of granular and powder ingredients include:

Granulars

Powders

Flakes

Pellets

Extruded pieces

There are many kinds of food processing plants that transform granular and powder ingredients into a vast array of food products. These plants produce common foods such as instant noodles or pastas, dry condiments including spice mixtures and specialised foods like nutrient supplements or baby formula. They manufacture food products that then require further processing before being ready for consumption such as baking ingredients or bread dough. Specialised plants produce animal feeds and dry pet foods.

These food processing plants combine granular and powder ingredients in two major ways. They can blend a number of solids together, or with minor and micro ingredients such as flavorings and enzymes, to make products like spice mixtures or baking ingredients. They can also mix solids with liquids to form semi-solids, making products like bread dough. Read on for more on mixing and blending.

A list of foods covered by these types of food processing plants include:

Bread and cereals

Animals and pets

Drinks and sweets

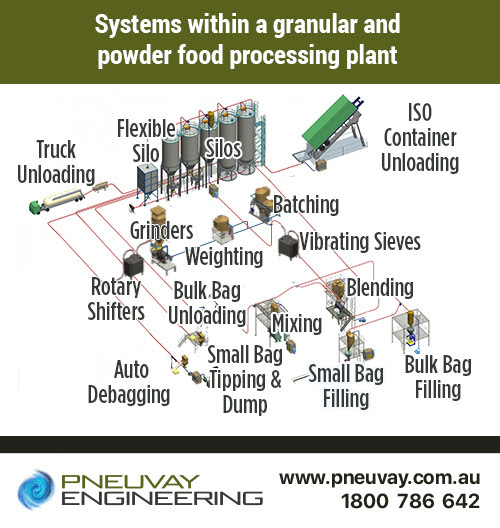

Granular and powder food processing plants are sophisticated and complex. They use advanced engineering and innovative automation technology. To understand how these plants work and what they do, we use a modular structure to break the flow of material handling into several distinct stages, which are connected and follow a typical order. Pneumatic conveying is used to transfer granular and powder ingredients within or between stages.

These stages and their typical order are:

Constant quality output is an essential requirement for every stage in the flow. This is achieved with quality systems that are reliable, easy to maintain and which integrate seamlessly within the plant. These systems need to allow for efficient cleaning which maximises hygiene and minimises downtime.

Any granular and powder food processing plant can be represented as one or more stages within this material handling flow. In general, each stage has custom control panels, and suitable dust collection and filter systems. Depending on the situation, some stages may require dehumidifiers and magnetic separator systems.

Granular and powder ingredients are transferred within and between stages by use of pneumatic conveying. This type of conveying occurs generally within and between the unloading and processing stages.

There are four types of pneumatic conveying used, and which method is used depends on many factors. The methods used are lean phase pressure conveying (DPPC), lean phase vacuum conveying (LPVC), dense phase pressure conveying (DPP) and dense phase vacuum conveying (DPVC). Note that other terms are used including:

Food processor companies will generally operate a combination of old and new plants of varying production capacities. They will consider refurbishing or extending an existing food processing plant when they need to:

They will also consider building a new plant to relocate or expand operations if the new location offers strategic benefits.

Granular and powder food processing plants are typically configured to operate in one of two types. In one type the plant is focused on delivering a high throughput on a single product. The other type of plant has the flexibility to vary production capacities on a set of different products. All plants have numerous requirements to which they operate, including aspects such as:

Plants follow a modular structure, which allows them to be broken down into one or more material flow stages. The systems and accessories within each stage can be documented. The conveying methods used to transfer materials between and within stages can also be detailed. This modular structure is an effective way to represent any granular and powder food processing plant and gives a clear picture of how it operates.

The combination of plant requirements and modular structure is what an industry systems integrator needs in order to develop an ideal solution for the food processing company. The industry systems integrator would draw on its commercial experience in material handling of granular and powder ingredients and specialised resources to provide complete solutions that include:

It would be considered best practice to involve the industry systems integrator in the development and documentation of the plant requirements. This is so their expertise can be used to ensure design decisions are made correctly from the start. Their experience can also help uncover concealed factors that may affect production or have undesired effects on or within the stages of the food processing plant.

Another important best practice consideration is to involve an industry systems integrator with the ability to interpret, design and supply the plant's control panels. This expertise is valuable in streamlining solution delivery and maximising integration.

An ideal industry systems integrator suited to granular and powder food processing would have successfully delivered many different types of plants in various configurations. This broad range of plants would include:

Simple examples

These are examples where the plant development is only one or two stages:

Complex examples

These are example where the plant development is more than two stages:

Systems within a granular and powder food processing plant

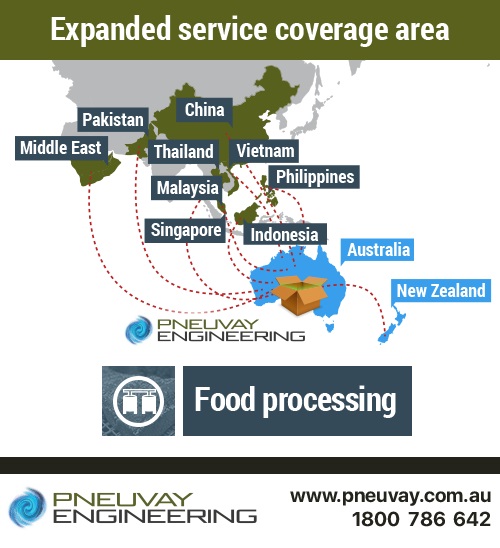

Our recent join with Pneu Powder Systems (the Asia-Pacific industry leader) provides a greatly expanded base of knowledge, expertise and experience in the material handling of granular and powder ingredients in the food processing industry. We now offer specialisation in food processing to the same level we provide in aviation, mining, manufacturing and transport. As an industry system integrator, Pneuvay can now provide complete solutions and deliver:

We have a combined portfolio of many large to multinational companies including:

Australia

Asia-Pacific and Middle East

Our head office is in Australia but we now have access to offices in Singapore, Malaysia, Vietnam and the Philippines. Our coverage area for providing system integration for material handling of granular and powder ingredients in the food processing industry has increased to cover Asia-Pacific and Middle East as well as Australia.

If you would like assistance in the development of granular and powder food processing plant, feel free to call on 1300721458 or contact us.

Expanded coverage area for system integration

in the food processing industry

Get social with us and see the latest news items from:

Vortex Global is proud to appoint Pneuvay Engineering as its sole agent for New Zealand.

Read on to find out how this set a new standard for bulk material handling solution for Australia and New Zealand.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541