See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

See our latest projects and be updated with recent news and features

happening in the world of pneumatic conveying, materials handling

and industrial vacuum systems.

Monday, June 23, 2014

Pneuvay Engineering's Managing Director, Michael Francis (Managing Director) and Paul Malcolm (Engineering Manager) share their expertise in this specialised field by answering these common questions. Read their response to the top five questions asked by industries about pneumatic conveying systems.

Michael Francis and Paul Malcolm - pneumatic conveying experts of Pneuvay Engineering

Of all the pneumatic conveying questions, this is by far the most common. Pneumatic conveying is the technology where air or gas is used to propel granular or powder material in an enclosed pipe. It comes from the Greek term 'pneumatikos', meaning 'of wind or air. The technology can operate as either a vacuum or as a pressure system. In more technical terms, the ratio of kg of air to kg of product can be expressed by the designer in the terms of lean phase or dense phase pneumatic conveying systems.

Question #1: What is pneumatic conveying?

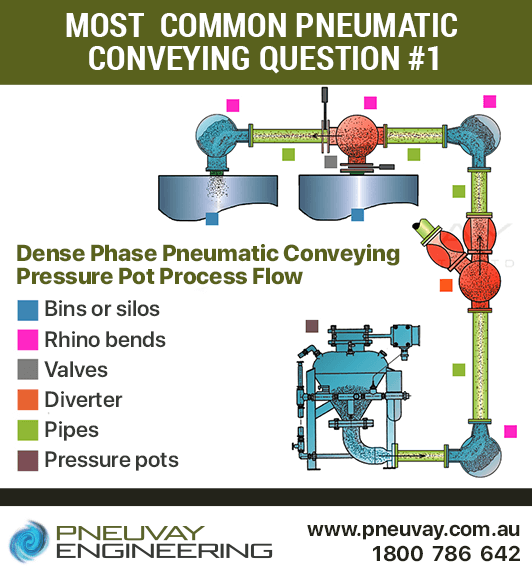

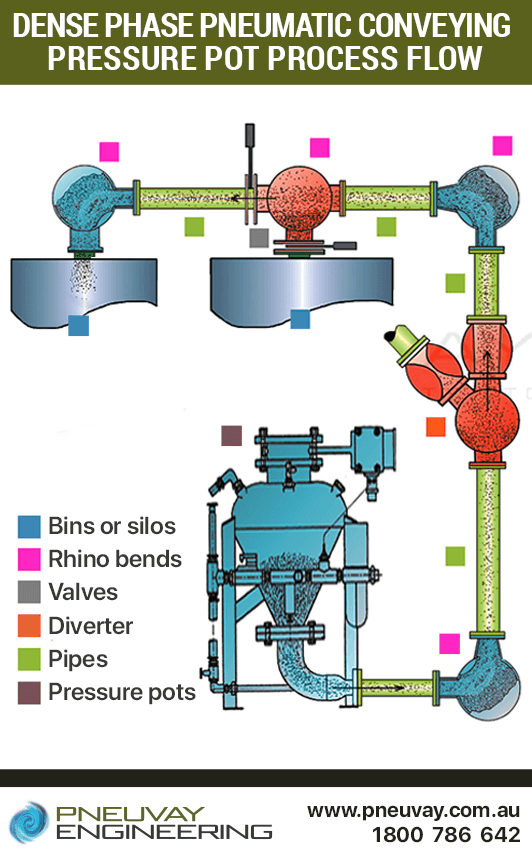

Here is an example of how a dense phase pneumatic conveying system process flows material.

Dense phase pneumatic conveying system process flow

Pneumatic conveying systems are used in various industries, particularly those related to school wood and metal shops, grain and seed storage, and plastics and paper converting.

Industries that commonly use pneumatic conveying systems include:

Other industries where they are used in specific situations include:

Waste recovery plants include pollution control and water treatment facilities.

Question #2: What industries benefit from pneumatic conveying systems?

We commonly encounter queries and problems regarding the difference between air volume and air pressure within a pneumatic conveying system. Sometimes systems have been added to, or rates have been increased above the original design, without proper calculations having been made. As a result the system fails to meet production expectations, with blockages and a drop in performance being experienced.

Question #3: What is the most common pneumatic conveying problems you find?

A major cause of these unwanted inefficiencies are existing systems that have been installed in an ad hoc manner. This is a common error made by inexperienced engineers who, while understanding the merits of pneumatic conveying systems, lack the knowledge to realise the technical design techniques.

Question #4: What are the major causes of pneumatic conveying system inefficiencies?

We take time to analyse the individual pieces of equipment used in the pneumatic conveying system. These include:

Question #5: How does Pneuvay respond to pneumatic conveying errors and inefficiencies?

You need an expert engineer to help you decide if a pneumatic conveying system will work best for you. Talk to us and we'll carefully analyse the characteristics of your conveyed materials:

Question #6: What pneumatic conveying systems will work best for me?

Mechanical conveying systems have their own advantages. Pneumatic conveying systems, however, are the preferred choice when conveying powder and granular materials over a long distance. Pneumatic conveying has the following advantages over mechanical:

Question #7: How are pneumatic conveying systems better than mechanical conveyors?

Pneumatic conveying systems work best at rates up to 100tph. Inefficiencies may still happen though, in small pipe lengths or in very high conveying rates. In cases like this we recommend the use of mechanical conveying systems to maximise the use of direct power.

Question #8: What disadvantages do pneumatic conveying systems have??

We supply various pneumatic conveying equipment, components and systems. These include Vortex Valves and the Donaldson Dust Collector Systems, including its dust control collectors, extractors and extraction systems. Other products we install, maintain and supply to industries include:

Question #9: What pneumatic conveying products do you offer industries?

Pneumatic conveying systems may require significant initial outlay. The pay-off, however, comes over time (return on investment), as they provide reduced maintenance costs and increased productivity gains. The greater return on investment will depend on your specific circumstances.

Question #10: What advice can you give to industries wishing to benefit from pneumatic conveying systems?

Feel free to contact us at 1300721458 if you have more pneumatic conveying questions. We are happy to help get a better understanding of how your business may benefit from a pneumatic conveying system.

Check out to with now latest updates on our See us on LinkedIn and consider following us.

Get social with us and see the latest news items from:

Discover how we support the night Australian mining industry with our pneumatic conveying systems.

Read on for details about projects we've completed in Western Australia, Queensland, and South Australia.

Pipe and Tube Compression Couplings

Industrial Dust Collectors Systems

Dust Collectors Filters, Cartridges and Bags

Pneuvay Engineering Pty Ltd - Copyright 2020

ABN 49 006 027 541